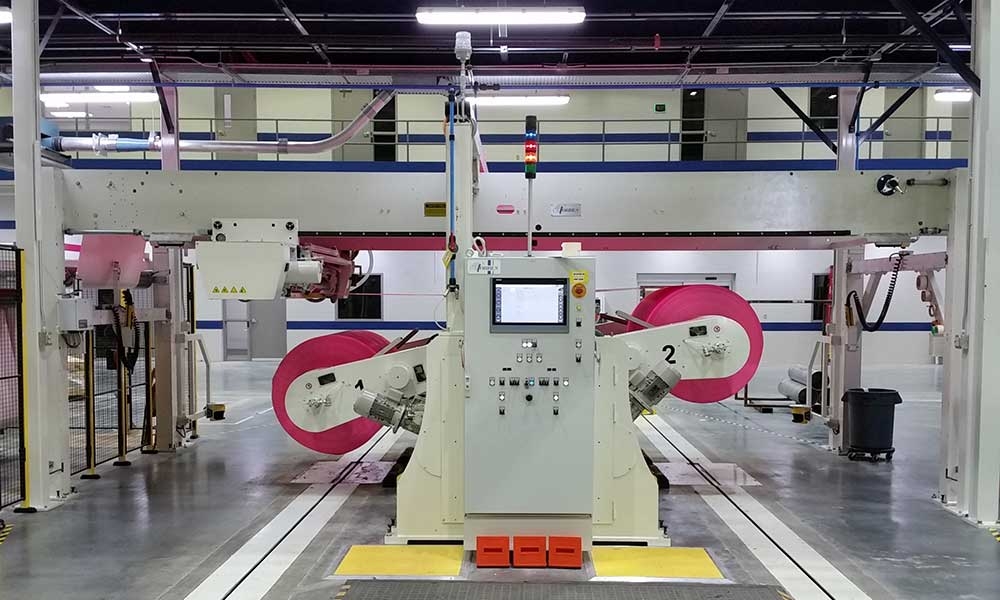

LTS Splicer

Constant Tension Splicer

The LTS is a medium-speed, high-performance splicer that MTorres offers with various configurations, depending on the required splicing speed, and can reach a splicing speed up to 470 m/min (1570 fpm). It is ideal for gypsum, paper, cardboard and other rigid materials such as laminated papers used in printing, extrusion coating, lamination processes, etc. in numerous applications. Following its standard configuration, the LTS has been designed to work with floor pick-up type unwinders.

Butt Splicing Unit

The Butt Splice unit is integrated into a carriage that moves horizontally from the splice position to the preparation positions. Vacuum bars hold the paper in position during the splice preparation enabling the operator to easily and quickly prepare the new splice.

Multiple Store Capacity

Depending on the required splicing speed, a double, triple or quadruple store would be supplied to be able to feed material (paper) to the line during the splicing process, without reducing the working speed. The rollers are made of aluminum with an appropriate surface treatment, depending on the material being unwound. The store position is a “floating system” controlled by a pneumatic clutch. The desired web tension will be determined by the pressure in the clutch, and it is an input value in the HMI.

Tension control

The second function of the store is to work as a dancer roll during the unwinding process to maintain constant web tension, absorbing possible tension fluctuations that may arise. A pull and brake, controlled by an AC motor with an AC drive, helps to control the web tension. A deviation of the store position from its set point affects the speed of the pull and brake, and returns it to the working position without changing the web tension. During the splice sequence, the pull and brake accelerate the new reel, maintaining constant web tension at the splicer exit.

Settings

| LTS Options | Improvement Area | |

|---|---|---|

| R.O.C. 1) | Automatic splicing to minimize waste | Raw material savings |

| External Pull and Brake (included in rack) | Unwinder web tension isolation - process | Process quality |

| Edge guide system | Web Alignment | Process quality |

| Special rollers | Adaptation to demanding | Process quality / coverage range |

| Butt Splice | Butt Splice | Process quality |

| Motorized Chucks | Unwind Control | Process quality / maintainability / energy saving |

| Auto loading / unloading | Reel Handling | Process efficiency - productivity / ergonomics |

| Conveyors | Reel Handling | Process efficiency - productivity / ergonomics |

| Core finder | Reel Handling | Process efficiency - productivity/ ergonomics |

| Lifting - Peeling | Reel Handling | Process efficiency - productivity / ergonomics |

| Other Core diameters | Cores | Customization |

| Chuk Adapters | Cores | Customization |

| TorresFactory | Operational availability monitoring and improvement tool for productivity improvement | Process efficiency - productivity |

| Rockwell Platform | Control | Customization |

| UL regulations | Norms | Customization |

| MTorres Unwind Tests | Tests | Optimization |

| Other non-CE language | Documentation | Customization |

| Imperial unit of measure | Documentation | Customization |

| Recommended Spares Kit | Spare Parts | Maintainability / process efficiency |

1) for substrates from 120/130 gsm.

The splice is made by detecting the color change between the core and the web, therefore a color change detection is needed.

The web must be attached to the core across the entire width. It cannot be partially detached from it.