Digitization

Digital twin

The design processes of Mtorres have been adapted for the creation of digital twins of the equipment that it designs, builds and implements. The deliverables of the automation projects in Mtorres may include digital twins.

- Digital twins of plant design and process

- Digital twins including simulation of physical band processes as well as their integration with line control

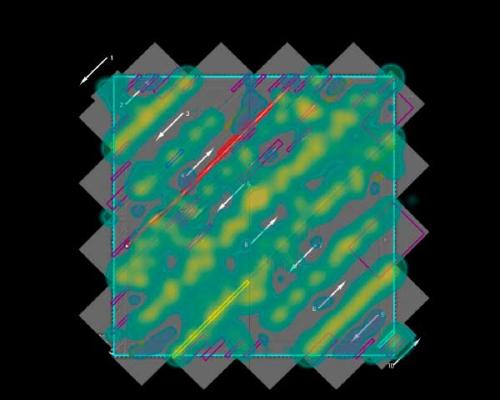

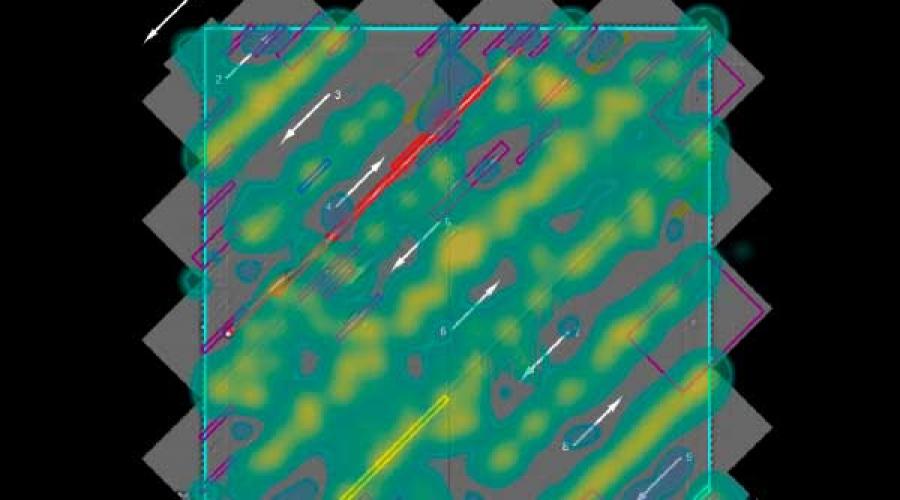

- Kinematic digital twins of the machine for sequence optimization and collision simulation

- Digital twins of the machine and its automation to speed up change management in automation software and to enable virtual training

- Digital twins of the pieces produced, where the key information of the manufacturing process of a piece in Torresfactory is generated

The advantages are

- Decision making and simulations of productivity and processes in concurrent engineering phases

- Accurate simulation of software and automation changes without taking up machine time in production, optimizing your start-up

- Possibility of advanced training for operators without taking up production machine time

- Possibility of advanced analysis of quality data and process of a part for continuous improvement

Torresfactory

The original concept and MTorres Vision are to transform manual and heavy tasks with extremely high-quality standards into automated processes. Automating processes means not only providing the tailored equipment for the specific process but also being able to upgrade and improve the effectivity of the machine, adapting it to new process, materials or regulations, thus extending its lifetime.

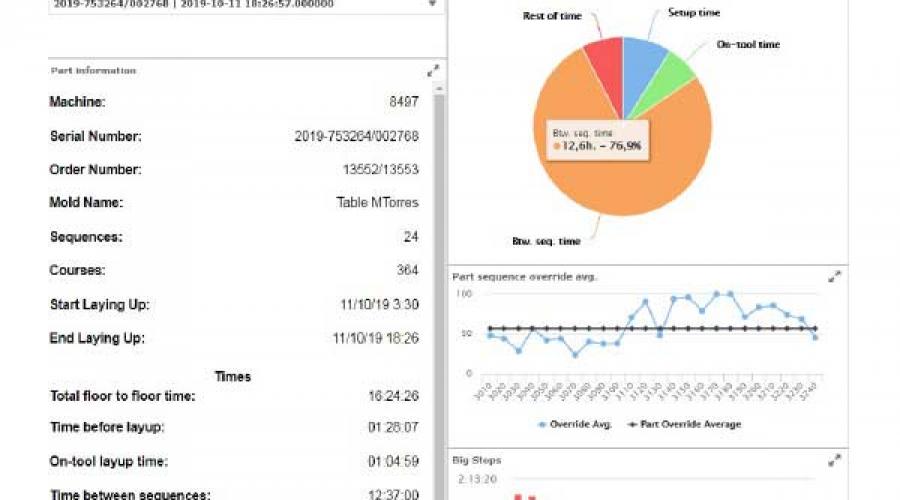

The introduction of new sensors and on-line quality information into the process makes possible now that current availability and productivity issues could be predicted and detected before they really happen. This means that Mtorres machines could self-diagnose and in the long term self-tune and self-repair. For that purpose Mtorres has developed a platform that gathers the relevant machine data, calculate the key process indicators, trigger predictive insights dealing not only with maintenance but also with process improvements

TORRESfactory is a data acquisition and processing platform for MTorres machines. Specific analysis algorithms are programmed in order to

- Maximize the productivity and efficiency of the machines

- Extend the lifetime of the asset

- Foresee and prevent recurrent failures and unplanned stops

- Optimize the maintenance plan of the machines

- Speed up new process developments of the customers

We collect machine data and key variables seamless and in parallel to the machine operation. The data is gathered using TORRESfactory Edge device. Torresfactory software Apps extract efficiency and maintenance insights from data and present the machine summary indicators in a dashboard as well as send the machine related information to customer third party’s applications (MES, ERP) using a standard machine API.

References by sectorOptimization of equipment and processes

If you need to extend the life of your equipment, improve its performance, quality or adapt it for compliance with certain regulations, we can carry out technical audits to assess your current situation, propose the necessary actions to achieve your goals and follow up the implementation and success.

Our technical expertise and knowledge of the process together with our data analytics and remote support capabilities makes us ideal for a successful process audit.

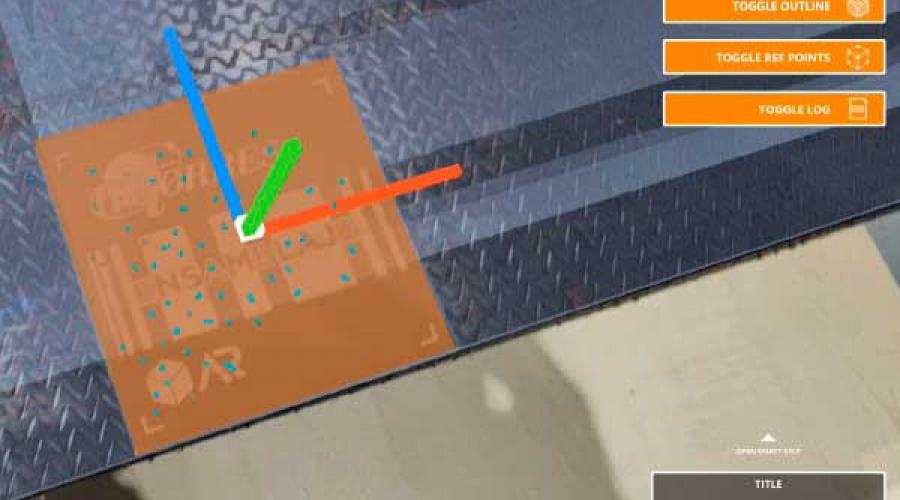

References by sectorAugmented reality

Mtorres develop specific Augmented Reality applications for the cases in which adding extra layers of data or design information is a key factor fore the optimization of the process. Examples of this:

- In-process design tooling for composites assembly instructions

- Composites lamination reworks based on on-line inspection data

- Machine data and aftersales services support scenarios