TorresTape – Dry fiber

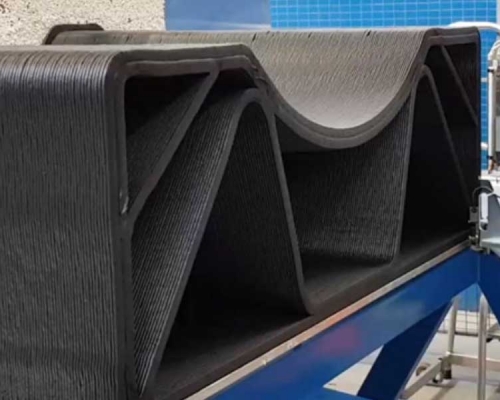

MTorres has developed, during the last two years, high-performance dry fiber raw material formats for automatic lamination (AFP) and infusion and RTM applications. These formats seek to reduce recurrent costs in automated manufacturing processes with composite material, both carbon fiber and fiberglass.

Thanks to the experience in the Converting sector, along with more than 25 years of work in the design and implementation of manufacturing processes for composite materials, MTorres has patented a format manufacturing process that allows obtaining a material with adequate behavior to wrapping and infusion, with a critical cost reduction compared to similar formats.

The reference magazine CompositesWorld dedicated an extensive article about this latest development. To read the complete article Click here

Format features

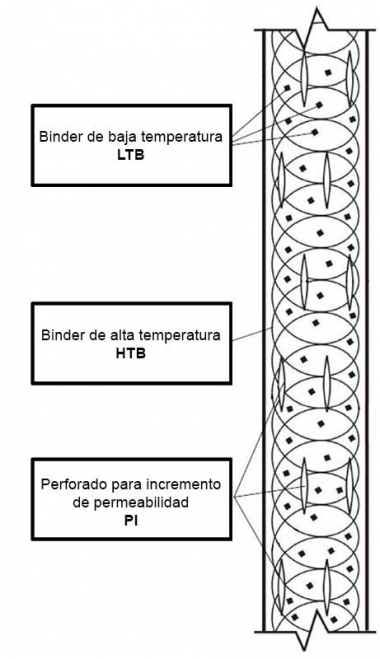

Low temperature binder (LTB):

Application of powder binder to cohere the fiber, enabling the AFP process

High temperature binder (HTB):

Binder applied with spiraling that allows the width of the format to be kept constant, providing the necessary lateral cohesion, and improving permeability in the plane

Perforating to increase permeability (PI):

Small grooves are created and consolidated, without cutting, damaging or distorting the fibers, to obtain maximum permeability

Available formats

Currently, MTorres has standard formats of carbon fiber material in widths of ½” (12.7mm) and 2” (50.8mm), and fiberglass in 2”. The usual weights are between 150gsm and 600gsm depending on the final application.

½” format in carbon fiber

2” format in carbon fiber

2” format in fiberglass

Additionally, as it is a process developed entirely by MTorres, we have the ability to adjust the material to other needs, both in terms of width and grammage or processability (permeability, fiber type, & hellip;)

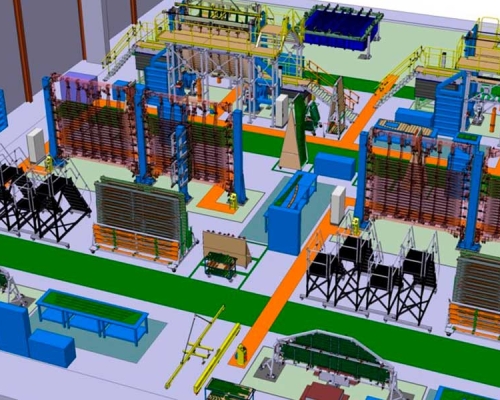

Production capacities

Pilot line for the manufacture of narrow-format dry fiber, with a production capacity of 150 tons per year

Pilot line for the manufacture of wide-format dry fiber, with a production capacity of 300 tons per year

Downloads

You will find all the technical information specified in the product sheet.