Innovative solutions for industrial processes

MTorres designs innovative, competitive and integral solutions for the execution of industrial processes. Although most of our work has been developed in the aerospace, packaging and paper converting sectors, the accumulated knowledge and experience allow us to study other sectors of activity.

More than forty-five years working end-to-end with customers all over the world allow us to understand better than anyone else the specific keys to a wide range of processes and apply our portfolio of capabilities to cover them, either by supplying the technologies, developing turnkey projects of complete manufacturing lines or facilities, or providing engineering services, support or optimization of the means already available.

The automation and robotization implicit in our proposals are key to make layouts more flexible, to smooth the production start-up and increase the production rate, to reduce the customer´s investment in production means, and to maximize the return on investment in the shortest possible time.

Likewise, since the beginning of Industry 4.0, MTorres has incorporated new means and technologies, as well as carried out its own development of digital tools; with the intention of increasing the added value of the solutions we provide to our customers.

Every year, since the formation of the company, a relevant part of the economic benefit we obtain is reinvested in R&D. This allows us to keep our products at the technological forefront and to develop new proposals for other applications or markets.

Process Engineering

At MTorres we know how to design from scratch or optimize existing production processes to achieve the levels of quality, productivity and efficiency that each product requires.

To do this, we use a wide range of programs to simulate variables, define operating sequences and calculate equipment and other resource needs:

- Specialized CAD-CAE solutions for ENSURING A SMOOTH ENTRY INTO PRODUCTION

- Simulation of manufacturing parameters, times and yields

- Kinematic simulation (avoidance of collisions and dry runs

In recent years we have incorporated digital tools such as the digital twin or big data analysis that allow us to access the process parameters in any of its phases and design models to detect errors and/or optimization opportunities or to evaluate relevant changes before their execution.

In addition, we have our own facilities to perform tests and trials of your applications in environments similar to the productive ones, which considerably reduces the analysis time and the uncertainty associated with changes or new designs.

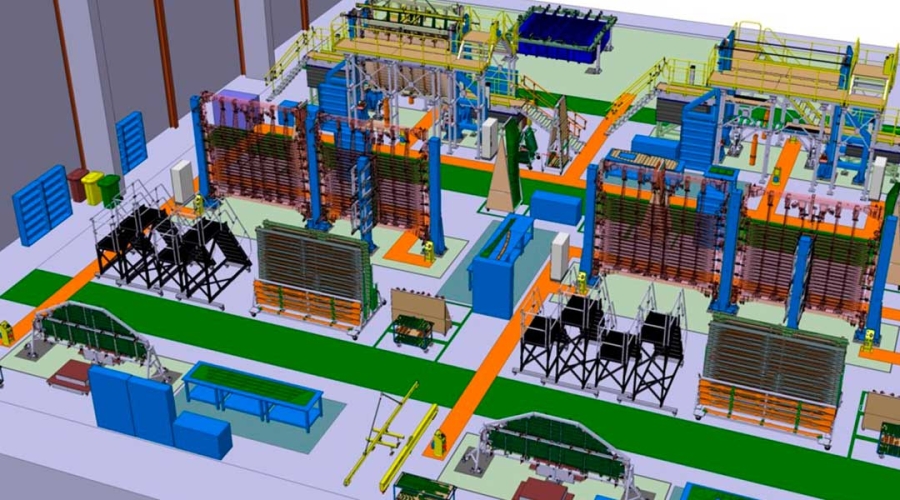

References by sectorLines and turnkey plants

The design, assembly and start-up of manufacturing lines and/or assembly of complete production plants requires not only a mastery of the underlying technologies and processes but also a very solid capacity for planning and control of operations.

MTorres has highly qualified resources and mature management methods to execute large-volume projects:

- Layout design and civil engineering studies

- Planning of the flow of materials and logistics, combined with a detailed calculation of times and processes.

- Interface Parameterization

- Dimensioning, definition and supply of necessary technologies, whether own or third-party (integration of subcontractors)

- Software integration for production control

- Commissioning

- Operation support

- Maintenance and optimization of processes, ratios and recurrent.

In recent years we have developed several projects for complete plants and large manufacturing lines in the Aeronautical sector that incorporate our own and third-party technology, with a high degree of customer satisfaction

References by sectorR&D and ERDF projects

MTorres has its own patented technology for the manufacture of large components by means of additive manufacturing. By means of an innovative manufacturing process, the system does not require tempered chambers and allows the manufacture of large parts economically and with a significant reduction in manufacturing times.

R&D Projects

Help to improve competitiveness

MTorres, Diseños Industriales SAU has received a grant from the Government of Navarra under the 2024 call for aid to improve competitiveness.

File No.: 0011-1463-2024-000006

Industrial Technologies for a Sustainable and Competitive Aeronautics - TIANA

MTorres, Diseños Industriales SAU, participates in the development of the TIANA project, whose overall objective is to address the research of disruptive solutions for aircraft structure components based on intelligent, automated and high cadence manufacturing technologies and the use of new materials with improved functionalities that allow obtaining more integrated and lighter structures, contributing to a significant reduction in both consumption and weight of the aircraft as a whole, as well as recycling technologies that improve the carbon footprint and ensure the circular economy. On the other hand, the project addresses the research of architectures adapted to new zero-emission auxiliary power systems with H2.

The TIANA project will contribute to increase manufacturing rates to levels never reached before, bringing the production capacity up to 100 aircraft per month, and to the reduction of the unit cost of manufacturing aerostructures, thanks to the optimization of the industrial manufacturing and assembly line.

The TIANA project consortium is composed of AIRBUS OPERATIONS S.L., ACITURRI ENGINEERING S.L., M.TORRES DISEÑOS INDUSTRIALES S.A.U., OBUU TECH S.L., TECNATOM S.A., and ACCIONA CONSTRUCCIÓN S.A.

The project has been funded by the CDTI and financed by the European Union - NextGenerationEU.

Innovative Aerostructures for Emission Reduction - AIRE

MTorres, Diseños Industriales SAU, participates in the development of the AIRE project, which aims to research a set of new sustainable technologies that lay the foundations of knowledge for future developments of elementary parts and the research of assemblies to reduce pollutant emissions both in their production processes and in the aircraft once in service. To this end, several lines of research will be addressed in different fields related to the area of aircraft structural engineering and factories of the future. All this will result in greater efficiency and a reduction in the volume of CO2 emitted into the atmosphere as a result of manufacturing and assembly activities in the sector and air traffic itself, so AIRE is a project aligned with the Sustainable Development Strategy 2030, based on responsible and sustainable production and consumption.

The AIRE project consortium is composed of ACITURRI, AERONAUTICA INGENIERIA ENERGIAS RENOVABLES Y SEGURIDAD LABORAL, AIRBUS DEFENCE AND SPACE, MTORRES, PRINCIPIA and TITANIA.

This project has been funded by the CDTI and supported by the Spanish Ministry of Science and Innovation.

Research on new technologies, materials and processes associated with the hydrogen value chain - ValorH2

MTorres, Diseños Industriales SAU, participates in the development of the ValorH2 project, whose objective is the research on technologies, materials and processes in different stages of the hydrogen value chain: generation, compression, storage and transport, and use, on the one hand in the refueling of hydrogen in vehicles (fuel) and on the other in a process of methanation of CO2 recovered in chemical industry (chemical reagent), with the aim of increasing efficiency, reducing the economic cost, and minimizing the carbon footprint in all of them.

The ValorH2 project consortium is composed of HIPERBARIC, ACITURRI, ADISSEO, ARIEMA ENERXIA, DESARROLLO DE MAQUINAS Y SOLUCIONES AUTOMÁTICAS, DGH and MTORRES.

This project has been funded by the CDTI and supported by the Ministry of Science and Innovation.

Towards the new industrial ecosystems of 2030, driven by the new generation of cognitive machine tools, able to learn and act autonomously and empathetically - MHAYA

MTorres, Diseños Industriales SAU, participates in the development of the MHAYA project, whose objective is the development of a new generation of conscious machine tools, endowed with cognitive and cognitive capabilities, and incorporating high levels of empathy with people. These conscious machines, acting as a core element of the industry, will have the ability to connect both among themselves and with all other systems in the industry, to assist operators by managing and materializing the collective intelligence of the factory, will be able to learn from experiences, and to incorporate learning into new adjustment and control loops to act autonomously on the processes changing the conditions and the result, helping to boost and accelerate the industrial revolution of the XXI century.

The MHAYA project consortium is composed of NICOLÁS CORREA, ANÁLISISIS Y SIMULACIÓN, DANOBAT, IBARMIA, MTORRES, NIDEC ARISA, ONA ELECTROEROSION and ZAYER.

This project has been funded by the CDTI and supported by the Ministry of Science and Innovation.

Disruptive helicopter project of the future - LIDER

MTorres, Industrial Designs S.A.U., participates in the development of the Disruptive Future Helicopter - LIDER project, whose objective is the design of new aerostructures for current or future helicopters, whose standards are in line with the new global needs, especially in terms of energy efficiency and decarbonization, aerodynamic improvements, environmental impact and circular economy, of course, without detriment to flight and operational capabilities, environmental impact and circular economy, of course, without detriment to flight and operational capabilities, and under a comprehensive approach that contemplates both the design of the new elements, research on the use of new lightweight materials and the development of new manufacturing, assembly and mounting technologies that meet the new specifications.

The LIDER project consortium is made up of AIRBUS HELICOPTERS, ACITURRI, IDEC, MTORRES, MECANIZADOS VITORIA.

This project has been funded by CDTI and supported by the Spanish Ministry of Science and Innovation.

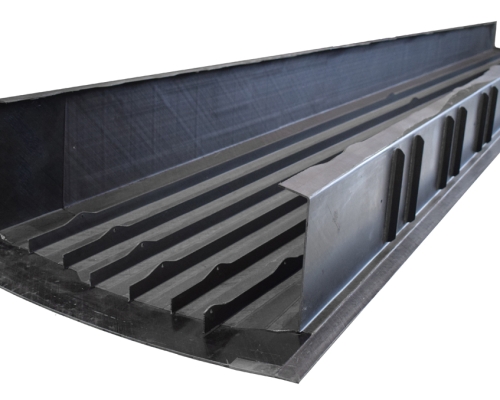

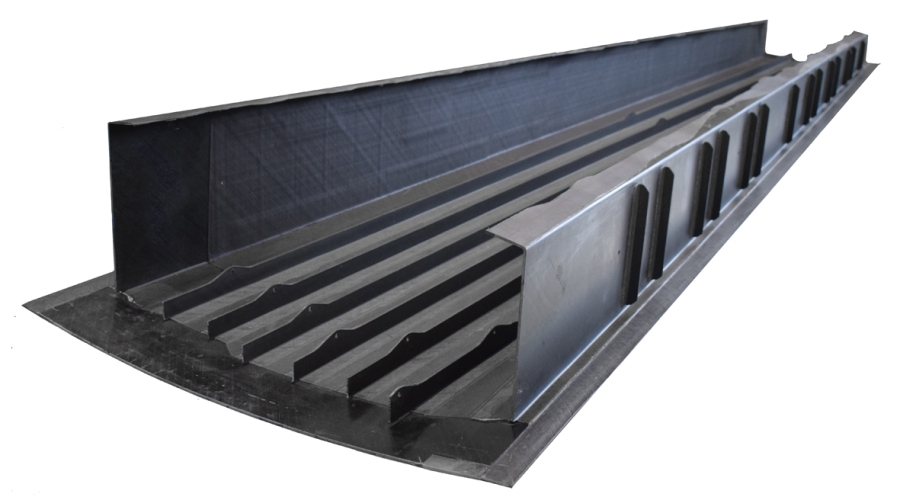

PROJECT 2020.08.ID+I.0042

MTorres, Diseños Industriales SAU, has obtained a grant from the Instituto de Fomento de la Región de Murcia (INFO) within the RIS3MUR COVID-19 PROGRAM, for the project ADDITIVE MANUFACTURING OF MOULDS FOR COMPOSITE MATERIAL COMPONENTS OF LARGE DIMENSIONS, with a grant of 128,845.40€. This action is co-financed by the European Regional Development Fund (ERDF) and the Instituto de Fomento de la Región de Murcia.

Technologies for industrially optimized advanced bearing surfaces in prepregs (PEGASO)

The PEGASO project aims to contribute to the development of a zero-emission aircraft. To this end, the project addresses research into intelligent, automated, high-cadence manufacturing technologies and new materials to improve the carbon footprint of aircraft, as well as recycling technologies to ensure the circular economy. PEGASO will focus on researching the automated, optimized, economical and eco-efficient manufacturing of a short-range, high throughput aircraft wing in carbon fiber prepreg composite material versus the current metallic solution.

PEGASO also aims to ensure the sustainability of its manufacturing processes, seeking to reduce the environmental impact by reducing energy consumption compared to current processes, reducing waste generated, recycling/reusing waste and using composite materials from renewable sources.

The PEGASO project consortium is composed of Airbus Operations, M Torres Diseños Industriales, Tecnatom, Industrias Delta Vigo, and Industrial Matricera Palentina (Inmapa).

This project has been funded by the CDTI and supported by the Ministry of Science and Innovation.

Aeronautical Components and Systems of the Future (AERCOST)

The overall objective of the AERCOST project is to obtain disruptive solutions for airframe components based on the use of new materials with improved functionalities and advanced manufacturing technologies that allow obtaining lightweight designs, contributing to a significant reduction in the weight of the aircraft as a whole.

This will improve its performance in terms of fire and impact resistance, allowing its integration with new zero-emission propulsion systems. All this will translate into greater efficiency and a reduction in the volume of CO2 emitted into the atmosphere as a result of air traffic. In addition, the automation of complex processes, which by their nature have been developed manually, is proposed, guaranteeing the evolution of procedures towards a digital environment, leaving behind the handmade character.

The AERCOST project aims to offer the market high value-added solutions that address the challenge of mitigating the environmental impact of air traffic by significantly reducing pollutant emissions, while guaranteeing excellent performance and quality control of the new designs.

The AERCOST project consortium is composed of Aciturri Engineering, Airbus Operations, M Torres Diseños Industriales, IDEC Ingeniería y Desarrollos de Composites, and Troqueles y Moldes de Galicia.

This project has been funded by the CDTI and supported by the Ministry of Industry, Tourism and Trade.

Advanced low-cost materials and processes for high-cadence aircraft (TRANSCEND)

The main objective of the TRANSCEND project is to innovate in the application of new materials and advanced manufacturing, assembly and inspection processes to obtain new aircraft structures in a wide range of fields, as well as highly repeatable parts for zero-emission aircraft with high production rates. The project will conceptualize the structures of this type of aircraft and performance grouping its typology by processes and materials that allow its automation and low cost, aiming that more than 60% of its structure can be made with them.

TRANSCEND will make it possible to research and develop high-performance solutions to reduce production costs in components with high manufacturing rates, as opposed to the current materials and processes of the aeronautical sector. This will be a strategic step forward, providing the Spanish industry with new knowledge and experience in the manufacture of a new variety of components and structures, subject to new cost, quality and safety requirements, depending on their function. TRANSCEND aims to achieve the economic balance of a product equidistant between the traditional aeronautics and the automotive industry by developing processes and materials more adjusted to the new functionalities of the 0 emission aircraft of the future.

The TRANSCEND project consortium is composed of Aernnova Composites Illescas, Aernnova Engineering Division, BIRKA, MTORRES, NORTE and EPROJECT4.

This project has been funded by the CDTI and supported by the Ministry of Science and Innovation.

Wet machining solutions

MTorres, Diseños Industriales SAU., has received financial support from the Center for the Development of Industrial Technology (CDTI) co-financed by the European Regional Development Fund (ERDF) through the Spanish Pluri-regional Operational Program 2014-2020 for the development of the R&D project entitled "SOLUCIONES DE MECANIZADO EN HÚMEDO" (WET MACHINING SOLUTIONS).

The project, with file number IDI-20200956 aims to expand the MTorres portfolio with a new product that allows the machining of both aluminum parts and fiber parts (FV and FC) through the wet-trimming process. The project has been carried out at the Torres de Elorz facilities from 02/24/2020 to 12/31/2021 with a budget of 232,923 €.

New conditioned materials for infusible laminates

MTorres, Diseños Industriales SAU., has received financial support from the Centro para el Desarrollo Tecnológico Industrial (CDTI) co-financed by the European Regional Development Fund (ERDF) through the Pluriregional Operational Program of Spain 2014-2020 for the development of the R&D project entitled "NEW CONDITIONED MATERIALS FOR INFUSIONABLE LAMINATES".

The project, with file number IDI-20191330, aims to develop a new material format based on carbon fiber and glass fiber in dry format for the intensification of the use in automated manufacturing processes of components for the wind power sector and other industrial sectors of great relevance such as: naval, railway and automotive, likewise, and for this purpose it will proceed to develop a new fiber conditioning technology for the manufacture of laminate tape.

SMART-LAYUP Development of innovative automated fibre placement machine for composite fuselage manufacturing with high performance hybrid materials

MTorres participates in the SMART-LAYUP project in which it will develop an automatic taping system that allows the manufacture of hybrid fuselage (carbon fiber and with integrated layers of viscoelastic material) for regional aircraft, in order to benefit from all the advantages of using this type of materials.

This project has received funding from Clean Sky 2 Joint Undertaking under the European Union´s Horizon 2020 program under grant agreement no. 738114. The project started on February 01, 2017 and is expected to end on July 31, 2020.

This Project has received funding from the Clean Sky 2 Joint Undertaking under the European Union´s Horizon 2020 research and innovation programme under grant agreement No 738114.

New aeronautical structure connections

M.TORRES DISEÑOS INDUSTRIALES, S.A.U. has received financial support from the Centro para el Desarrollo Tecnológico Industrial (CDTI) co-financed by the European Regional Development Fund (ERDF) through the Pluri-regional Operational Program of Spain 2014-2020 for the development of the R&D project entitled "NEW JOINTS FOR AERONAUTICAL STRUCTURES". The project, with file number IDI-20180754, aims to develop a new modular system for joining aeronautical structures composed of automatic and interchangeable blind riveting, nut and collar insertion and sealing heads, capable of being incorporated on a robot coupled to a new mobile robotic platform or on an autonomous platform, capable of working inside Aero structures. This new system will increase the flexibility in the joining of aeronautical structures and reduce the process time, with the consequent reduction of costs and increase of quality and repeatability in the execution of the process. It will also greatly increase the safety and ergonomics of the people involved in the production process.

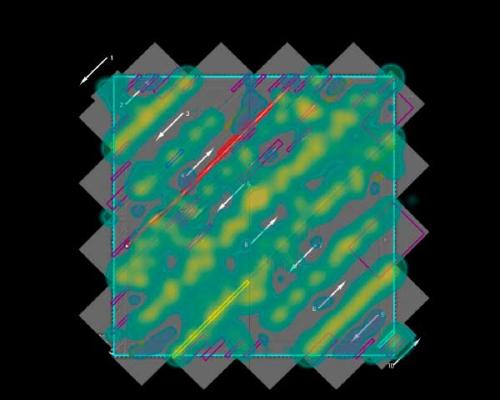

3D scanning system of complex surfaces at high speed for high precision applications in real time

The "3D SCANNING SYSTEM OF COMPLEX SURFACES AT HIGH SPEED FOR HIGH PRECISION APPLICATIONS IN REAL TIME" with Record No. TSI-100109-2015-5 has been co-funded by the Ministry of Industry, Energy and Tourism, within the Spanish National Plan of Scientific Investigation, Technological and Innovation Development for 2013-2016.

ZAero Zero-defect manufacturing of composite parts in the aerospace industry

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 721362. The project started on October 1st, 2016 and it will end on September 30th, 2019.

Automatic programming tool for surface machining

The project entitled "AUTOMATIC PROGRAMMING TOOL FOR SUPERFICIAL MACHINING" with File No. TSI-100109-2016-6 has been co-funded by the Ministry of Energy, Tourism and Digital Agenda, within the National Plan for Scientific Research, Development and Technological Innovation 2013-2016.

Carbon fiber automation technologies for strategic industries

M.TORRES DISEÑOS INDUSTRIALES, S.A.U. has received financial support from the Center for the Development of Industrial Technology (CDTI) co-financed by the European Regional Development Fund (ERDF) through the Multi-regional Operational Program for Intelligent Growth 2014-2020 for the development of the R&D project entitled "AUTOMATION TECHNOLOGIES OF CARBON FIBER FOR STRATEGIC SECTORS". The project, with file number IDI-20150364, aims to develop automated technologies for the manufacture of components for the automotive sector in carbon fiber-based composite materials, reaching the demanded production rates and improving productivity ratios.

ERDF PROJECTS

PROYECTO 2020.08.ID+I.0042

M TORRES DISEÑOS INDUSTRIALES, S.A.U. ha obtenido una ayuda del Instituto de Fomento de la Región de Murcia (INFO) dentro del PROGRAMA RIS3MUR COVID-19, por el proyecto FABRICACIÓN ADITIVA DE MOLDES PARA COMPONENTES EN MATERIAL COMPUESTO DE GRANDES DIMENSIONES, con una ayuda en forma de subvención de 128,845.40€. Esta actuación está cofinanciada por el Fondo Europeo de Desarrollo Regional (FEDER) y el Instituto de Fomento de la Región de Murcia.

Nuevos materiales acondicionados para laminados infusionables

M.TORRES DISEÑOS INDUSTRIALES, S.A.U. ha contado con una ayuda financiera del Centro para el Desarrollo Tecnológico Industrial (CDTI) cofinanciada por el Fondo Europeo de Desarrollo Regional (FEDER) a través del Programa Operativo Plurirregional de España 2014-2020 para el desarrollo del proyecto de I+D titulado “NUEVOS MATERIALES ACONDICIONADOS PARA LAMINADOS INFUSIONABLES”.

El proyecto, con número de expediente IDI-20191330, tiene por objetivo desarrollar un nuevo formato de material basado en fibra de carbono y fibra de vidrio en formato seco para la intensificación del uso en procesos de fabricación automatizados de componentes para el sector eólico y otros sectores industriales de gran relevancia como: naval, ferroviario y automoción, asimismo, y para ello se procederá a desarrollar una nueva tecnología de acondicionamiento de fibra para la fabricación de cinta de laminado.

Mejora de la eficiencia energética mediante luminarias LED inteligentes

Proyecto acogido a la línea de ayudas de ahorro y eficiencia energética en PYME y gran empresa del sector industrial, cofinanciada por el Fondo Europeo de Desarrollo Regional (FEDER), y gestionada por el IDAE con cargo al Fondo Nacional de Eficiencia Energética, con el objetivo de conseguir una economía más limpia y sostenible.

- Título: MEJORA DE LA EFICIENCIA ENERGÉTICA MEDIANTE LUMINARIAS LED INTELIGENTES

- Código de expediente: FN-PGESI-2018-002946

- Beneficiario: MTORRES DISEÑOS INDUSTRIALES S.A.U

- Inversión total: 109.439,13€

- Importe de la ayuda: 27.717,64€

- Ahorro Energético Final estimado: 18,65 tep/año

Soluciones de mecanizado en húmedo

M. TORRES DISEÑOS INDUSTRIALES, S.A.U. ha contado con una ayuda financiera del Centro para el Desarrollo Tecnológico Industrial (CDTI) cofinanciada por el Fondo Europeo de Desarrollo Regional (FEDER) a través del programa Operativo Plurirregional de España 2014-2020 para el desarrollo del proyecto de I+D titulado “SOLUCIONES DE MECANIZADO EN HÚMEDO”.

El proyecto, con número de expediente IDI-20200956 tiene por objetivo ampliar el porfolio de MTorres con un nuevo producto que permita el mecanizado tanto de piezas de aluminio como de piezas de fibra (FV y FC) mediante el proceso de mecanizado en húmedo (wet-trimming). El proyecto se ha llevado a cabo en las instalaciones de Torres de Elorz desde el 24/02/2020 hasta el 31/12/2021 con un presupuesto de 232.923 €.

New joints of aeronautical structures

MTORRES INDUSTRIAL DISEÑOS, S.A.U. has received financial aid from the Center for Industrial Technological Development (CDTI) co-financed by the European Regional Development Fund (ERDF) through the Spanish Pluriregional Operational Program 2014-2020 for the development of the R&D project entitled “ NEW JOINTS OF AERONAUTICAL STRUCTURES”. The project, with file number IDI-20180754, aims to develop a new modular system for joining aeronautical structures made up of revolver-type blind riveting heads, inserting nuts and collars and sealing, automatic and interchangeable, capable of being incorporated on a robot coupled to a novel mobile robotic platform or on an autonomous platform, capable of working inside aerostructures. This new system will increase flexibility in joining aeronautical structures and reduce process time, with the consequent reduction in costs and increase in quality and repeatability in the execution of the process. As well as greatly increasing the safety and ergonomics of the people involved in the production process.

New smart lighting system

The company MTORRES DISEñOS INDUSTRIALES, SA has been a beneficiary of the aid for the Promotion of Energy Efficiency and the Use of Renewable Energies by companies within the scope of the ERDF 2014/2020 operational program for the Region of Murcia .

Title: NEW INTELLIGENT LIGHTING SYSTEM

File number: 4P18SFE00263

Object: The object of this aid is to increase the energy efficiency of the MTorres plant located in Fuente Álamo by replacing the current lighting with LEDs, as well as installing an intelligent lighting system that allows the expected energy savings to be obtained. This aid is financed by the Ministry of Employment, Universities, Business and the Environment and co-financed by the European Regional Development Fund (ERDF), within the ERDF 2014/2020 Operational Program of the Region of Murcia with a co-financing rate of 80%.

- Objective of the action: Advance in the evaluation and improvement of the energy efficiency of companies, in particular SMEs.

- Results of the action:

Annual energy savings: 15.17 toe/year

GHG emissions savings: 58.24 tCO2/year

- Processing status: Granted.

- Total investment made: 63,607.71€

- Financial support:

Total grant awarded: 19,082.11€

Financing from the ERDF: 15,265.69€

Percentage of subsidy co-financed by the ERDF: 80%

Smart lighting system

MTORRES DISEñOS INDUSTRIALES, SA has been a beneficiary of the aid for the Promotion of Energy Efficiency and the Use of Renewable Energies by companies within the scope of the ERDF 2014/2020 operational program for the Region of Murcia for the execution of the project entitled INTELLIGENT LIGHTING SYSTEM". The project, with file number 4P17SFE00065, aims to increase the energy efficiency of the MTorres plant located in Fuente Álamo by replacing the current lighting with LEDS, as well as an intelligent lighting system that will allow the expected energy savings to be obtained.

This aid is financed by the Ministry of Employment, Universities and Business and co-financed by the European Regional Development Fund (ERDF), within the ERDF 2014/2020 Operational Program of the Region of Murcia with a co-financing rate of 80% .

- Objective of the action: Advance in the evaluation and improvement of the energy efficiency of companies, in particular SMEs.

- Results of the action:

Annual energy savings: 15.20 toe/year

GHG emissions savings: 58,368 tCO2/year

- Processing status: Granted.

- Total investment made: 55,774€

- Financial support:

Total grant awarded: 16,732.20€

Financing from the ERDF: 13,385.76€

Percentage of subsidy co-financed by the ERDF: 80%

High-speed 3D scanning system for complex surfaces for high-precision, real-time applications

The project “HIGH SPEED 3D DIGITALIZATION SYSTEM OF COMPLEX SURFACES FOR HIGH PRECISION APPLICATIONS IN REAL TIME” with Nº File TSI-100109-2015-5 has been co-financed by the Ministry of Energy, Tourism and Digital Agenda, within the National Plan for Scientific Research, Development and Technological Innovation 2013-2016.

Automatic programming tool for surface machining

The project entitled “AUTOMATIC PROGRAMMING TOOL FOR SURFACE MACHINING” with Nº File TSI-100109-2016-6 has been co-financed by the Ministry of Energy, Tourism and Digital Agenda, within the National Plan for Scientific Research, Development and Technological Innovation 2013-2016.

Carbon fiber automation technologies for strategic sectors

MTORRES INDUSTRIAL DISEÑOS, S.A.U. has received financial aid from the Center for Industrial Technological Development (CDTI) co-financed by the European Regional Development Fund (ERDF) through the Pluriregional Operational Program for Intelligent Growth 2014-2020 for the development of the R&D project entitled &ldquo ;CARBON FIBER AUTOMATION TECHNOLOGIES FOR STRATEGIC SECTORS”. The project, with file number IDI-20150364, aims to develop automated technologies for the manufacture of components for the automotive sector in composite materials based on carbon fiber, reaching the demanded production rates and improving productivity ratios.