TorresPrint3D® - Additive manufacturing

MTorres has its own patented technology for manufacturing large components through additive manufacturing.

Through a novel process developed by MTorres, we have our own patented technology for manufacturing large components through additive manufacturing, our TorresPrint3D® product.

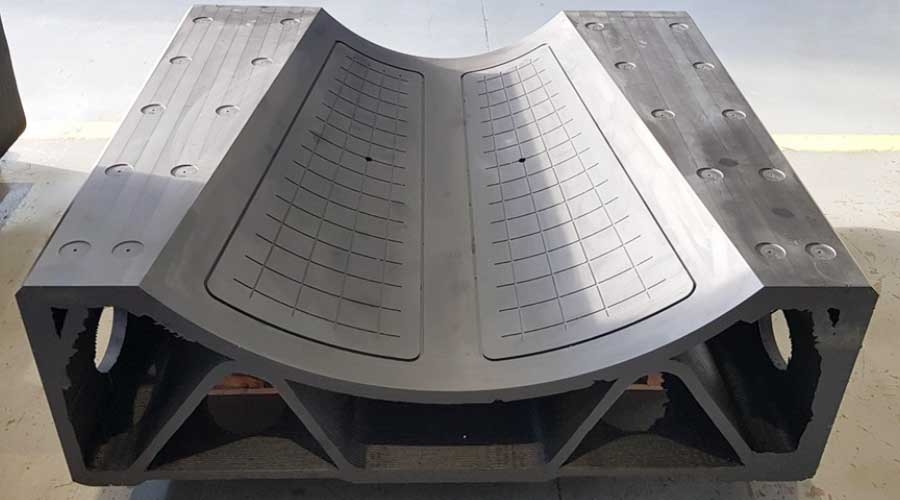

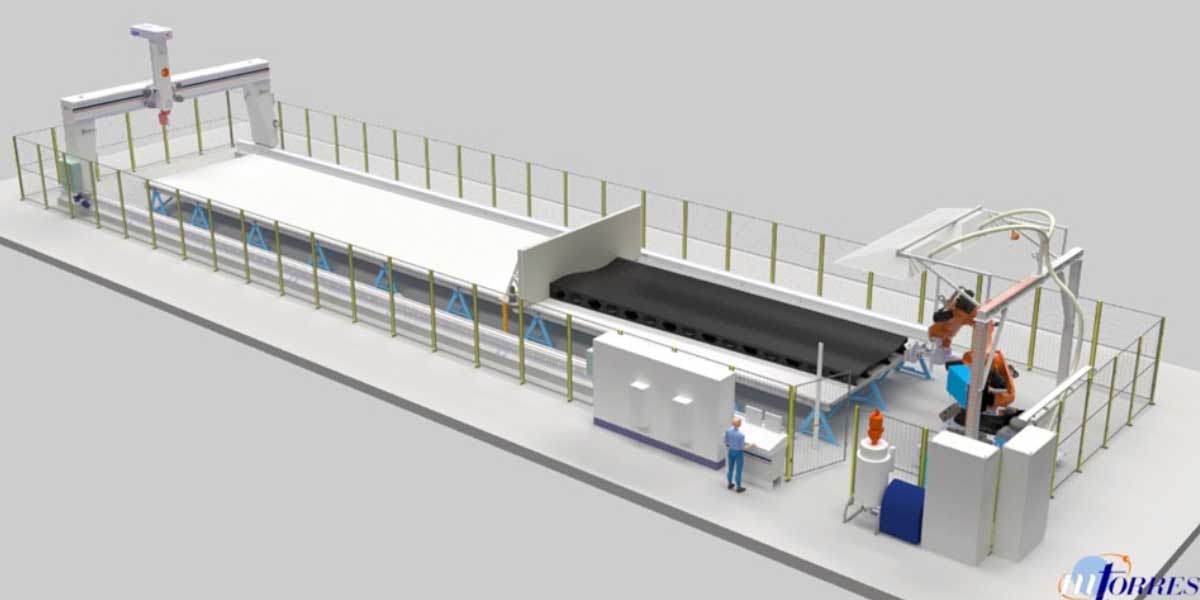

Machining mold in manufacturing process through TorresPrint3D®

Through a novel process developed by MTorres, we have our own patented technology for manufacturing large components through additive manufacturing, our TorresPrint3D product.

This system does not require tempered chambers and allows the manufacture of large-sized parts economically and with a significant reduction in manufacturing times.

Thanks to this technology, MTorres offers its clients:

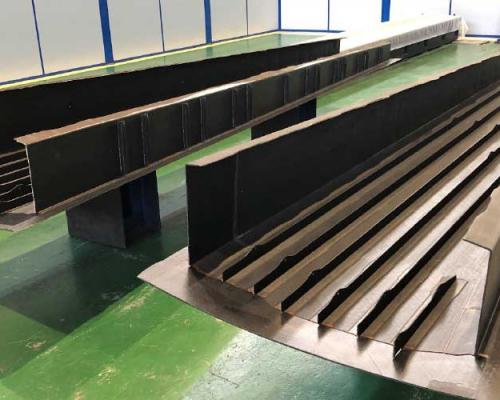

- Manufacture of tools for machining processes of large parts

- Manufacture of support tools for processes with large parts

- Manufacture of molds for composite parts

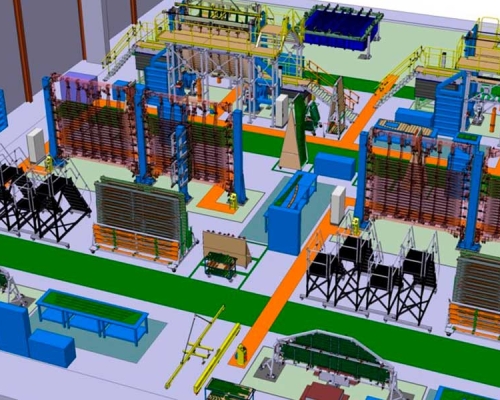

MTorres can take care of the manufacture and supply of these tools and moulds, or integrate additive manufacturing technology into our clients´ facilities to have its own capacity.

Technical features

- Maximum part dimensions: 25000 x 4500 x 1550mm

- System productivity: 35kg/h

- Maximum speed: 7000mm/min

- Maximum material melting temperature: 350ºC

- Local heating system: infrared

- Adjustable and interchangeable application nozzle.

- Materials: PPE, ABS, PESU, PC, PEI,…

Available capacities

TorresPrint3D on a robotic platform available at the MTorres facilities

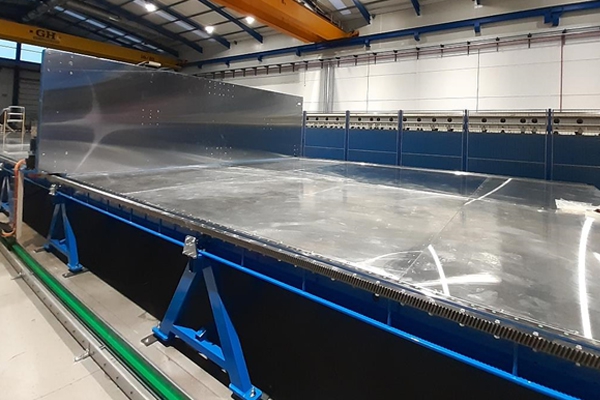

Mobile table with dimensions of 25 x 4.5m for the manufacture of large components

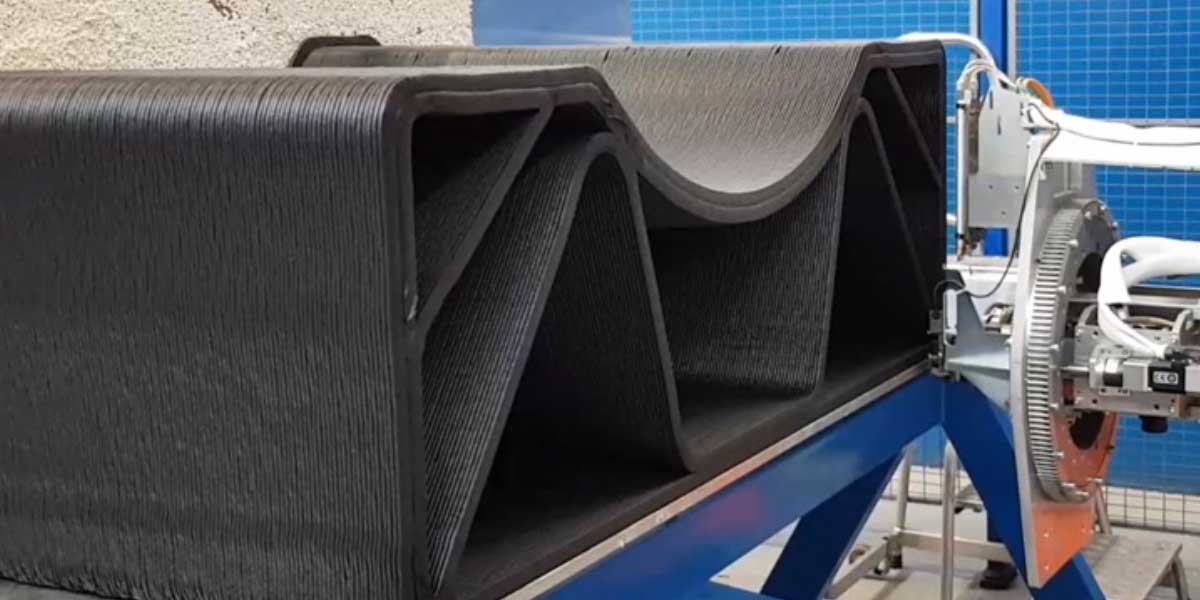

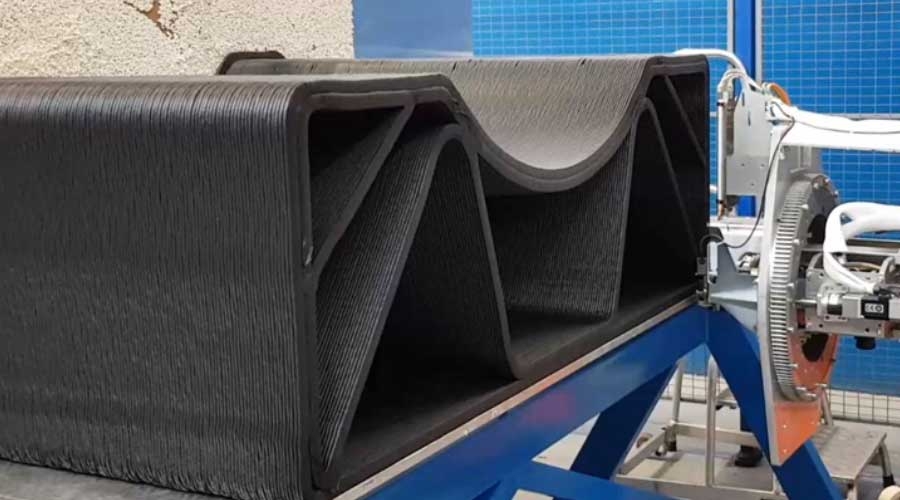

Detail of a piece during its manufacturing process

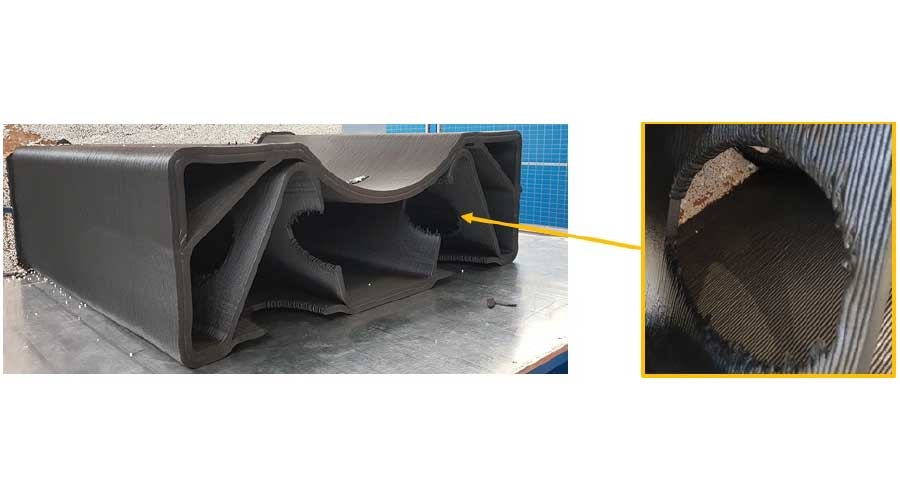

Results

Capacity of the process to generate internal windows for internal air conduction in molds and material savings