Engineering

The MTorres team has extensive experience in the development of manufacturing solutions for composite components, working for multiple sectors, thanks to which we offer the solution best suited to the needs of each specific project.

This experience allows us to offer a complete development of manufacturing processes based on complete composites, choosing the ideal technology for each specific application. Among the main tasks:

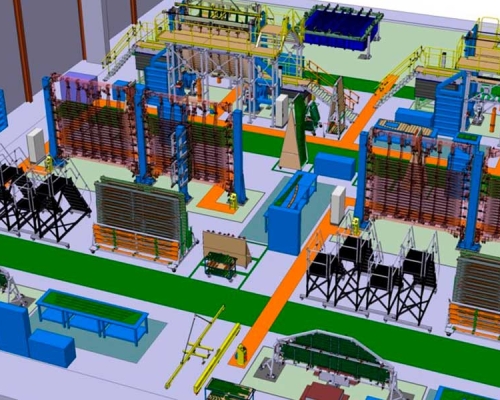

- Development of complete manufacturing and industrialization projects for composite components

- Materials

- Selection and development of materials and material formats

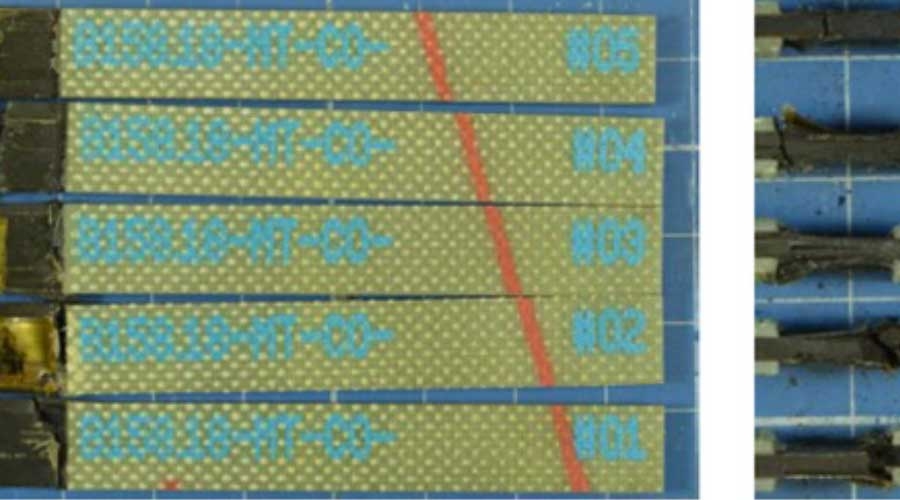

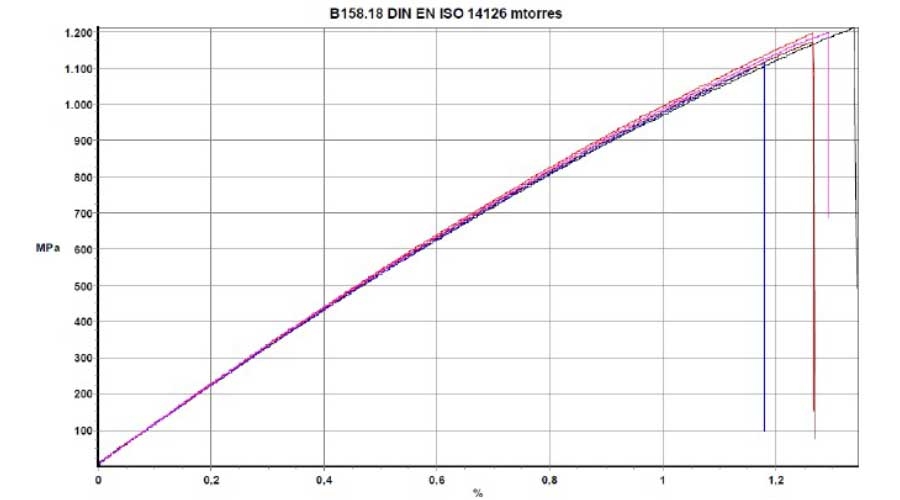

- Management and development of tests on materials and components

- Processes

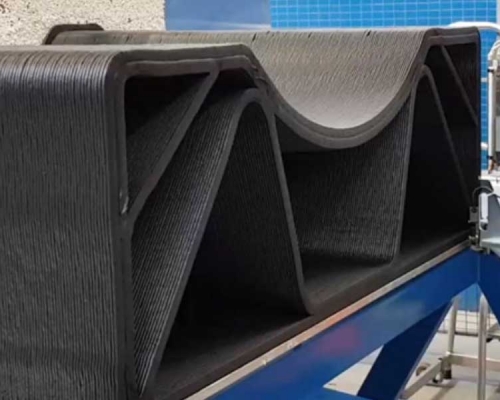

- Development and tuning of manual or automatic lamination processes in preimpregnated material or dry fiber material

- Development and tuning of infusion processes

- Selection and installation of consumables

- Curing, release and surface finishing

- Process simulation

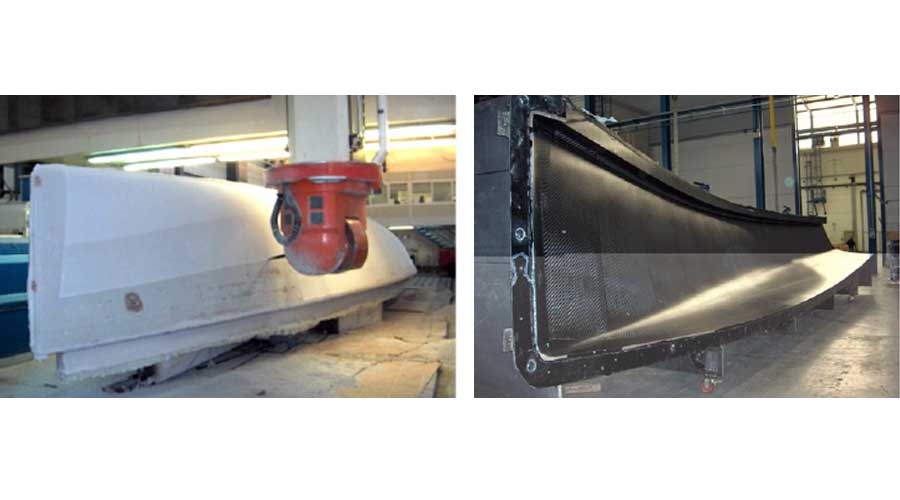

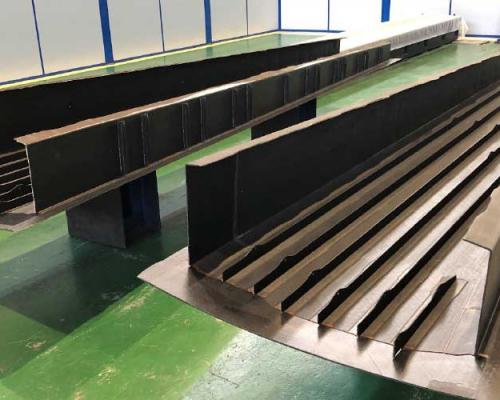

- Tools and molds

- Design, manufacture and set-up of molds and tools

MTorres is the right partner for the development of complete processes, developing the complete manufacturing process of composites, from the reinforcing fiber roving to the fully integrated final product, through solutions adapted to the specific needs of each project , selecting the optimal technologies and level of automation for your goals.

Complete projects

Materials

MTorres offers the development of dry fiber material configurations adaptable to the needs of each specific project

MTorres has extensive experience in the manufacture of specimens and test management by certified centers, along with their analysis and the generation of admissible designs .

MTorres is in charge of the management of specific analyzes for different materials, the analysis of results and the identification of optimal solutions for your project.

Processes

Automatic wrapping with dry fiber. MTorres can identify, for each specific case, which is the most effective process for your needs and develop any part or even the entire project to reach its industrialization.

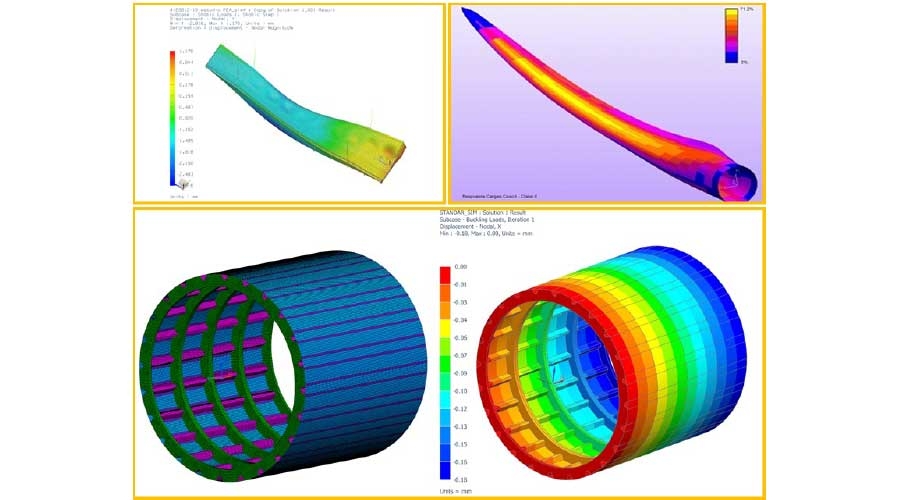

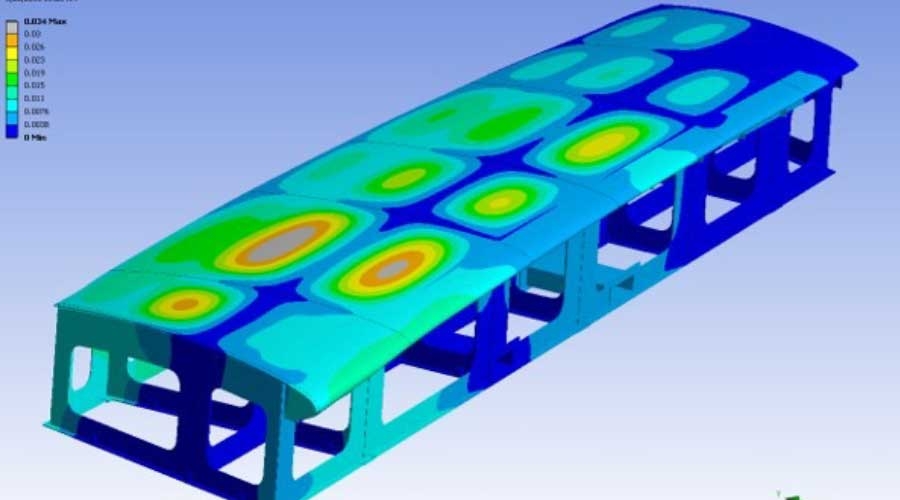

MTorres has its own capabilities in the development of structural simulations by FEM methodology and CAD design to support the development of specific projects.

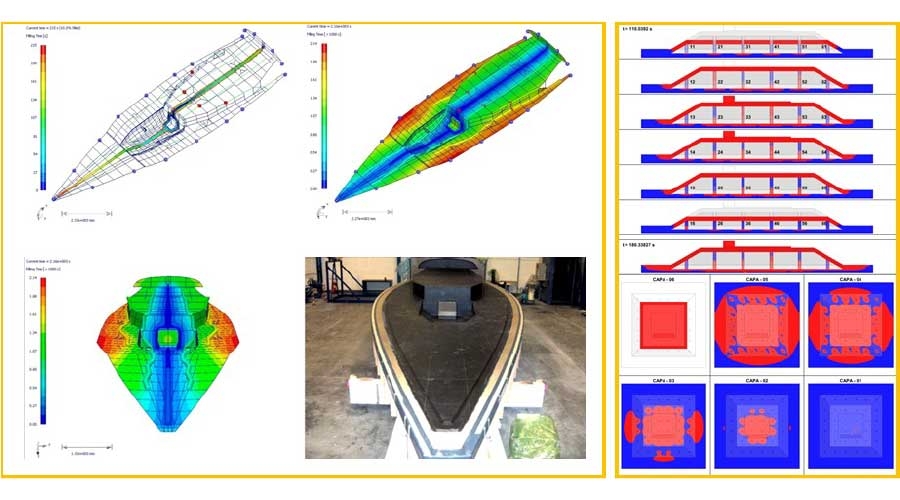

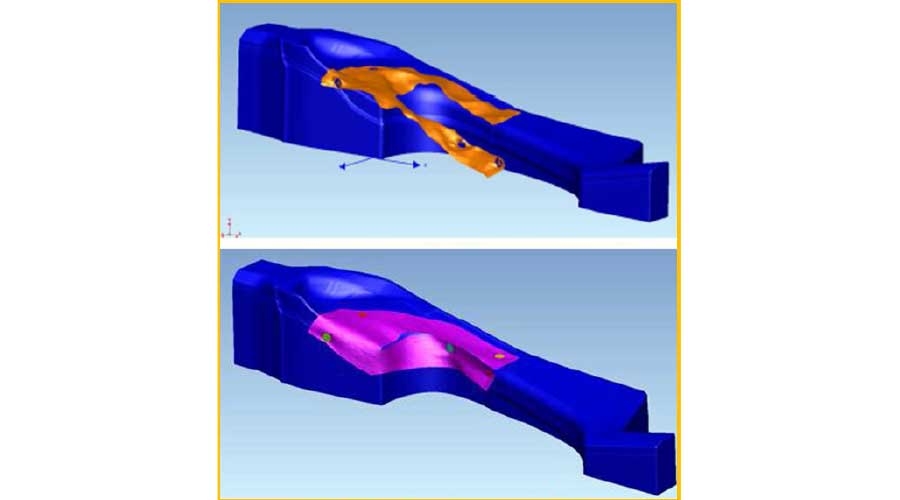

MTorres has its own tools for the design and optimization of complex infusion processes, in order to ensure optimal results from the first prototype.

MTorres has developed tools for the simulation of draping and fabric transfer processes that allow anticipating and avoiding problems of wrinkles and orientations in the final products.

Dry preform handling system by means of vacuum cups integrated in the IIAMS project

Tools

Structural response analysis of a mold

Mold and mold turning system

Development of a semi-automatic tool for gluing components in composite material

Development of an assembly dock for the automated assembly of wind turbine blades