LTX Splicer

LTX Splicer

A medium-high speed splicer ideal for paper, cardboard and other rigid materials.

LTX Splicer

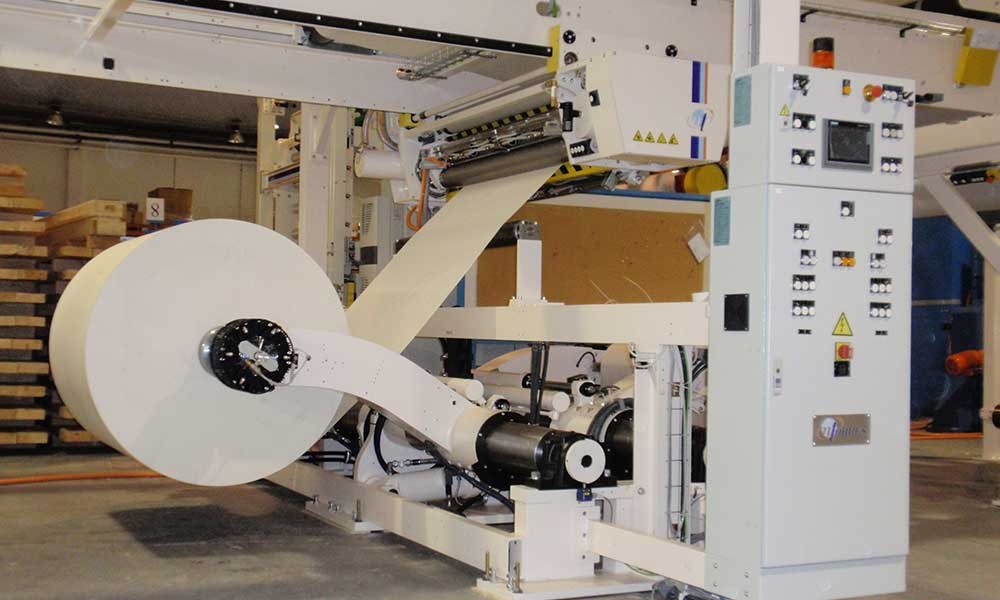

The Model LTX is a medium-high speed, high performance splicer that MTorres offers in several configurations, depending on the required splicing speed, which can reach up to 600 m/min (1968,5 fpm). It is ideal for paper, cardboard and other rigid materials such as laminated papers used in printing processes, extrusion, lamination, etc. in numerous applications such as aseptic liquid packaging. The LTX model in its standard configuration is designed to work with floor pick-up type unwinders.

Unwinder LTX-H Auto

End Splice Unit

The Testa Splicing Unit is integrated in a trolley that moves horizontally from the splicing position to the preparation positions. Thanks to the vacuum system on the preparation bars and its ergonomic position, the operator can prepare the new coil in a simple and fast way.

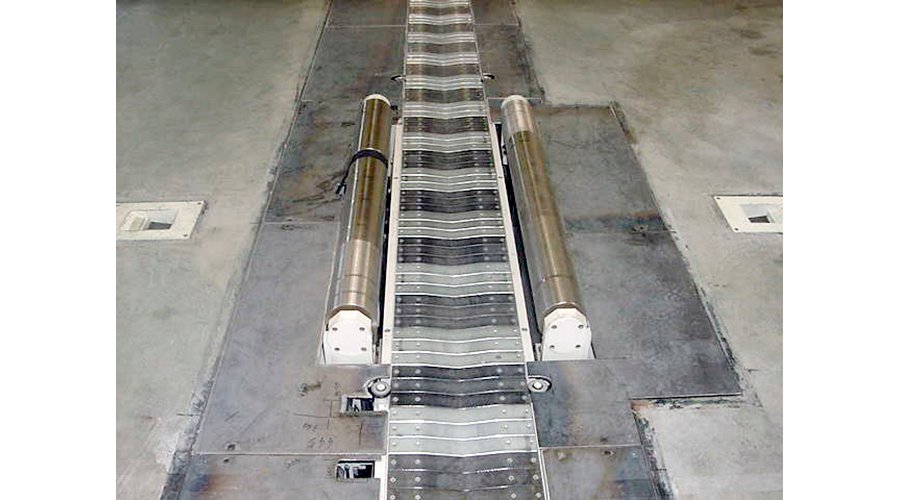

Multiple Storage

Depending on the required splice speed, a double, triple or quadruple storage can be incorporated in order to feed material (paper) to the line during the splice process, without the need to reduce the working speed. All the rolls are made of aluminum with the necessary surface treatment depending on the case. The storage is controlled by a floating system driven by a clutch. The desired output tension is selected by means of an electronic torque adjustment on the clutch.

Tension control

The second function of the storage is to act as a rocker arm during the unwinding process to keep the web tension constant, absorbing any tension peaks that may occur. A tension group controlled by an AC motor with frequency converter helps to control the web tension. A deviation of the storage from its zero set point has an impact on the speed of the tension group to recover the position without the tension varying. During the splicing cycle, the unit accelerates the new coil while maintaining constant web tension at the splicer output.

| LTX Settings | Improvement area | |

|---|---|---|

| R.O.C. 1) | Automatic splicing to minimize waste | Raw material savings |

| External group (included in rack) | Unwinder band tension isolation - process | Process quality |

| Aligner | Band Alignment | Process quality |

| Special rollers | adaptation to demanding bands | Process quality / coverage range |

| Autocut in preparation | Auto-cut splice preparation, without the need for the operator to cut the paper | Ergonomics - safety |

| Motor unwinding | Unwind control | Process quality / maintainability / energy saving |

| Auto load/unload | Reel handling | Process efficiency - productivity / ergonomics |

| Lanes | Reel handling | Process efficiency - productivity / ergonomics |

| Core finder | Reel handling | Process efficiency - productivity/ ergonomics |

| Elevator - Peeler | Reel handling | Process efficiency - productivity / ergonomics |

| Other cone diameters | Cones | Customization |

| Cone Adapters | Cones | Customization |

| "Factory Towers" | Operational availability monitoring and improvement tool to improve productivity | Process efficiency - productivity |

| Rockwell Platform | Control | Customization |

| USA Regulations | Regulations | Customization |

| MT unwind tests | Tests | Optimization |

| Other non-CE language | Documentation | Customization |

| Imperial unit of measure | Documentation | Customization |

| Recommended Spares Pack | Spare parts | Process maintainability / efficiency |

1) For substrates from 120/130 gsm.

The splice is made when the paper web is completely detached from the mandrel.

The band must be attached to the mandrel over its entire width, it cannot be partially detached from the mandrel.

Settings

Aligner

External group

Peeler elevator system