Surface Rewinder - TorresWINDER

Automatic transfer for multiple substrates

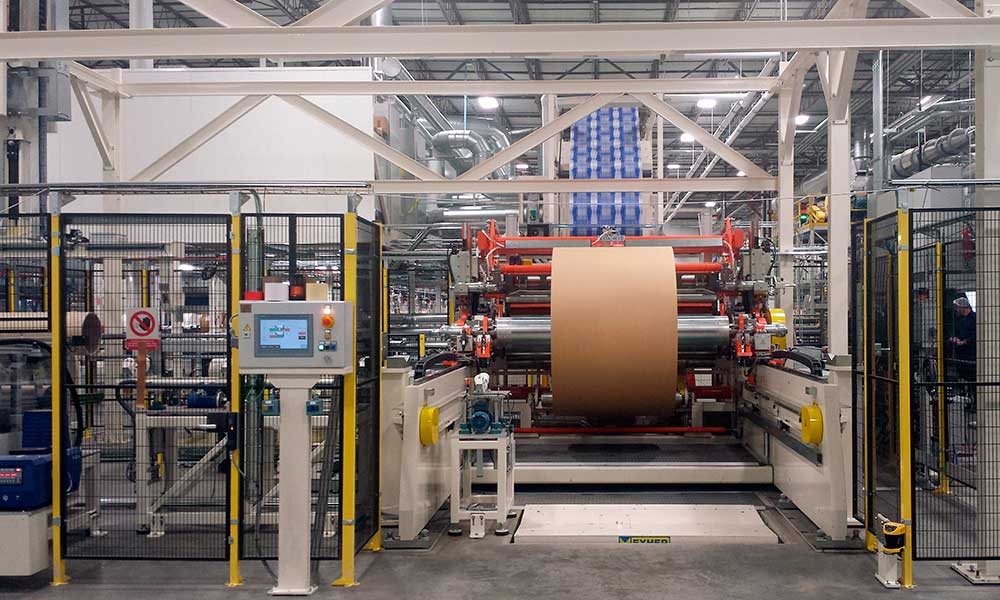

The TorresWINDER is a high-speed rewinder for paper, paperboard and other substrates is available for a wide range of reel sizes.

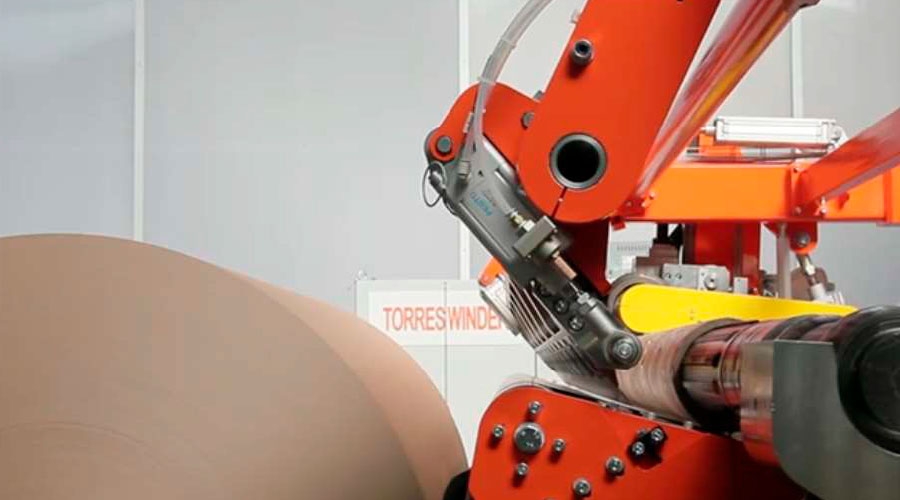

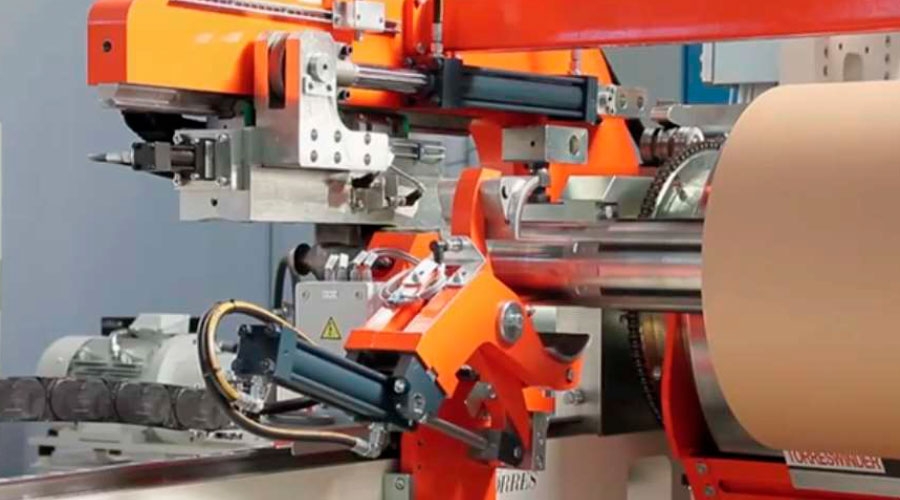

This is the industry’s first high speed rewinder that incorporates a contactless cutting system, increasing knife life and avoiding constant adjustment with web thickness variation.

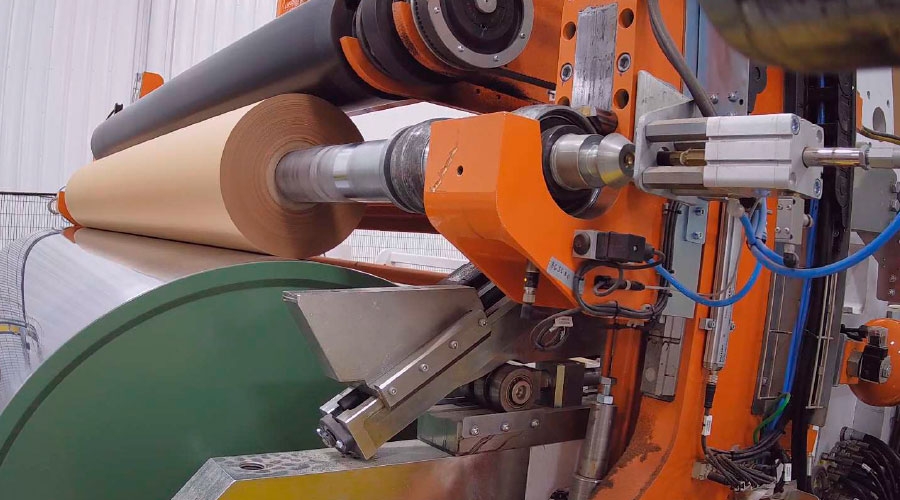

The TorresWINDER utilizes a motorized central winding drum and nip to control and build roll hardness throughout the rewinding process.

Process changes and full trouble shooting diagnostics are easily changed and viewd through the main HMI.

TORRESWINDER

Competitive advantages of MTorres Winders

The TorresWINDER is ideal for many applications and processes such as coating, laminating, printing, etc.

The latest safety and control technology has been incorporated into its design, allowing quick and easy integration with other control systems, whether it is a new installation or an upgrade to an existing line.

The TorresWINDER is available in different sizes (standar widths from 1400 - 2600 mm; diameter up to 2185 mm) and levels of automation, with multiple settings to ensure the best possible adaptation to the specific needs of each client.

Several options are available for the TorresWINDER, including trim/center slitting, automated core gluing, robotic shaft handling, and different PLC controls.

Options

The TorresWINDER model has different size configurations that allow it to be applied in widths from 1400 mm to 2600 mm (expandable on a customized machine) and rewind diameters of up to 2185 mm.

It can be used with different sizes of axles and has a robotic shaft handling system with different levels of task automation that allows you to optimize sequence times and work in high-speed processes.

It includes the contact less cutting system created by MTorres that improves the quality of the cut and makes system adjustment tasks easier.

Its individualized nip loading control and its advanced hardness control system allow you to obtain coils with high rewinding quality at high process speeds and with a transfer capacity of up to 800 m/min. A large number of options are available that will allow you to adapt to the most demanding processes.

| Settings / Options | Area of Improvement |

|

|---|---|---|

| Shaft Handling System | Robotic Shaft Handling, Core Feeding, Automation Levels | Process efficiency / ergonomics |

| Automatic Gluing | Core preparation using an automatic hot melt glue application system | Process efficiency / ergonomics |

| Extended Side Frames | Reel Handling | Process efficiency / ergonomics |

| Reel Support System | Hydraulic support rollers (mandatory with 4" shafts) | Increased coverage range / process quality |

| Turning Bars | Unit to Flip Web | Process quality |

| Web Guide | Ensure proper web path | Process quality |

| Slitter | Trim and Center Cutting Avalaible | Process quality |

| Different Shaft Diameters | Management of different shaft diameters Includes shaft pos | Customization |

| Rockwell Platform | Rockwell PLC, Drives, Display, communication | Customization |

| TorresFACTORY | Operational availability monitoring and improvement tool to improve productivity | Process efficiency - productivity |

| UL Certification | Marking / regulations | Customization |

| Factory Acceptance Testing | Tests | Machine Optimization |

| Other non-CE language | Documentation | Customization |

| Imperial Unit System | Documentation | Customization |

| Recommended Spare Parts | Spare Parts | Maintainability |

Features

Contactless cutting system

Contactless Cutting System

Finished Reel Brake

New Motorized Reel

Satellite Roller

Reel Support System

TorresWINDER Shaft Handling 1

Torreswinder Shaft Handling 2