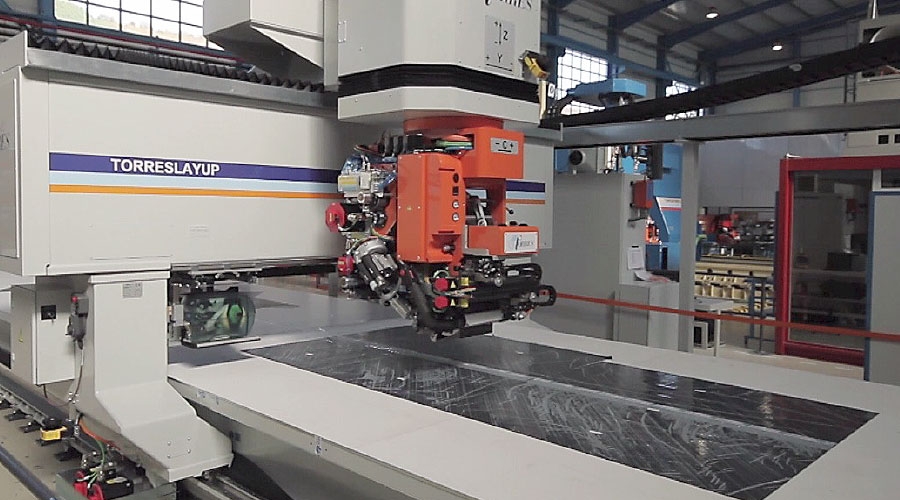

Automatic taping machine - TORRESLAYUP

Productivity and flexibility together in a perfect solution

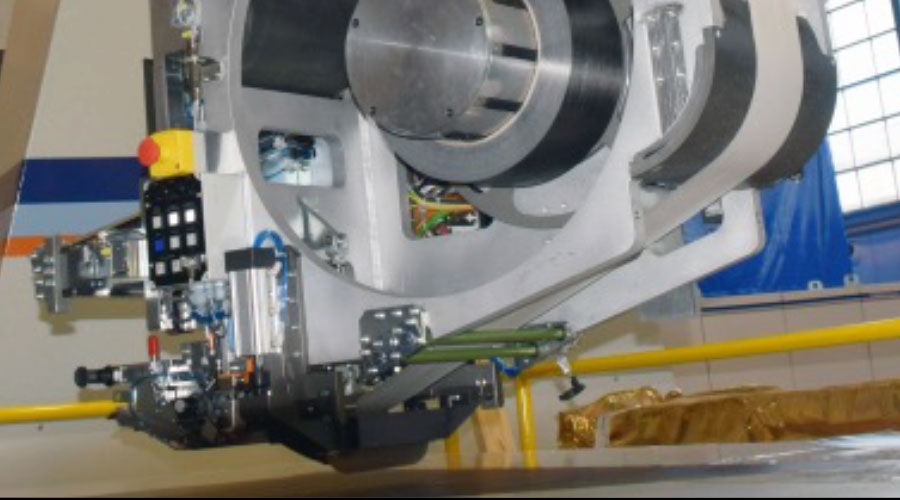

The specific design of the wrapping head provides the best results in terms of compaction, thus avoiding the need for debulking processes in the manufacture of the part.

The TORRESLAYUP works with tapes of 300, 150 (12”, 6”) of band width and can place a band width of up to 600 mm (24”) in multi-tape configuration.< /p>

There are also different multi-ribbon configurations available (4x150 mm – 4x75 mm– 2x150 mm) to be able to manufacture parts that require high "steering" power simultaneously using several belts suitable for that steering, but maintaining the bandwidth of the 300 or 600.

TORRESLAYUP machines are manufactured in different sizes to respond to customer requirements.

Its two ultrasonic blades, in a set of four NC-controlled axes, provide the ability to perform complex tape cuts during the placement process.

A laser defect detection system allows the machine to detect any defective part of the tape and prevents its placement on the part.

In addition, a sensitive and programmable band tension control system allows the machine to adapt to the most demanding compaction conditions on complex surfaces.

Among the available options, the machine can include an ultrasound cutting system for uncured parts just after lamination, thus eliminating the need for a dedicated machine.

The highly sophisticated TORLAY advanced programming software package allows the programmer to properly simulate, optimize and modify all the parameters associated with tapes, patterns and layers.

Then, a built-in post-processor automatically generates the CNC program for the parts.

Likewise, a software package is supplied for part history, in order to keep track of relevant events that have occurred in production.

Applications include the manufacture of flat, curved or high contour carbon fiber parts.

Applications

Multi-axis CNC machine to produce complex flight surfaces (Aerofoil) in carbon fiber.

- Single and Multitape configuration (2 & 4 tapes at a time)

- Tape width: 3”, 6” and 12” (75mm, 150mm and 30mm)

- Valid for the layup of slit tape and fabrics. Perfect solution for automatic layup of Non-structural materials

- Layup speed up to 140m/min

- Automatic Scrap removal system

- Multiple machine architectures: Gantry structure, Crossbeam, robotic arm and cantilever

- Automatic exchangeable head capability to combine different tape formats, materials and technologies into the same layup cell.

- Integrated vacuum table

La NUEVA MÁQUINA DE TORRESLAYUP de MTORRES es única en su género y ofrece la más alta productividad y fiabilidad para la colocación de componentes aeroespaciales de fibra de carbono. INCLUYE NUEVAS CARACTERÍSTICAS, como el sistema de eliminación automática de desechos que ayuda a impulsar el proceso y a maximizar la productividad en piezas con geometrías de capas complejas. Este nuevo cabezal es también la solución perfecta para ser combinada con la AFP en plataformas híbridas para el laminado de materiales no estructurales, tales como láminas de cobre expandido o tejidos de fibra de vidrio.

TORRESLAYUP Settings

- Own programming and simulation software. TORLAY

- Automatic head exchange capability

- Automatic Rototranslation system

- Ultrasonic ply cutting system

- Automatic knife change and calibration

- Automatic knife cleaning

- Integrated Laser projectors

- Automatic Defect Detection System

- Mould deviation compensation system

- Wireless pendant

- Dual working zone

ATL Heads

Single Tape head

V3 Single Tape head

Automatic Head Exchange

75mm Robot head

2x150mm MT head

4x150mm MT head

Settings. Machine Architectures

CANTILEVER TYPE

INTEGRATED TYPE

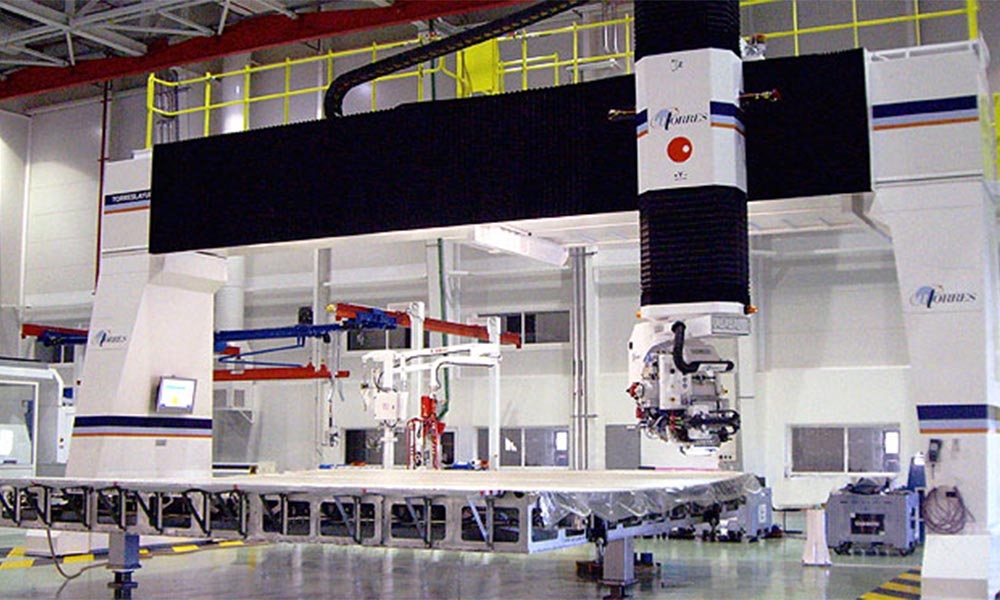

PORTAL GANTRY TYPE

ROBOT TYPE

Gantry Settings

- 2D & 3D layup

- Simple and double curvature parts geometries

- Highest dynamics machine in the market

- Simple lay-out easily accessible for operators

- Head exchange capability. AFP-ATL

- Valid for single and multi tape head

- Compatible with ultrasonic trimming

Machine architectures. Gantry

ATL Machine architectures. Gantry

ATL Machine architectures. Gantry

ATL Machine architectures. Gantry

ATL Machine architectures. Gantry

Settings. Integrated Gantry

- 2D layup

- High dynamics machine

- Simple lay-out

- Reduced foot print

- Integrated with vacuum table

- Head exchange capability. AFP-ATL

- Valid for single and multi tape head

- Compatible with ultrasonic trimming

Integrated Gantry

Cantilever Settings

- 2D layup

- High dynamics machine

- Simple lay-out easily accessible for operators

- Integrated with vacuum table

- Head exchange capability. AFP-ATL

- Valid for single and multi tape head

- Compatible with ultrasonic trimming

Cantilever

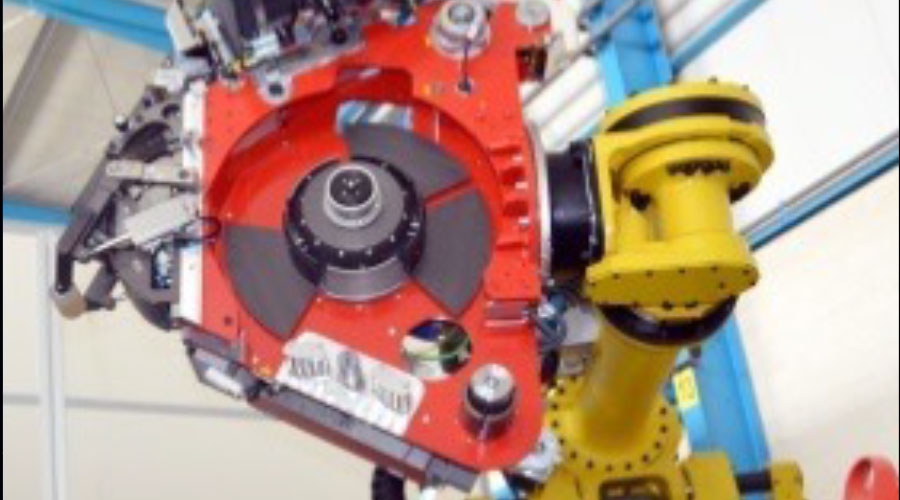

ATL Robot Settings "

- On ground. No special foundation requirements

- Small footprint

- Head exchange capability. AFP-AFP and AFP-ATL

- Single and multitape compatible

- Very versatile architecture. Easily integrable with other technologies

- KUKA robotic arm with SIEMENS controller

- Integrated with X carriage and 6’ axis

Robot