Torreslite

Special splicers for narrow reels up to 870 mm.

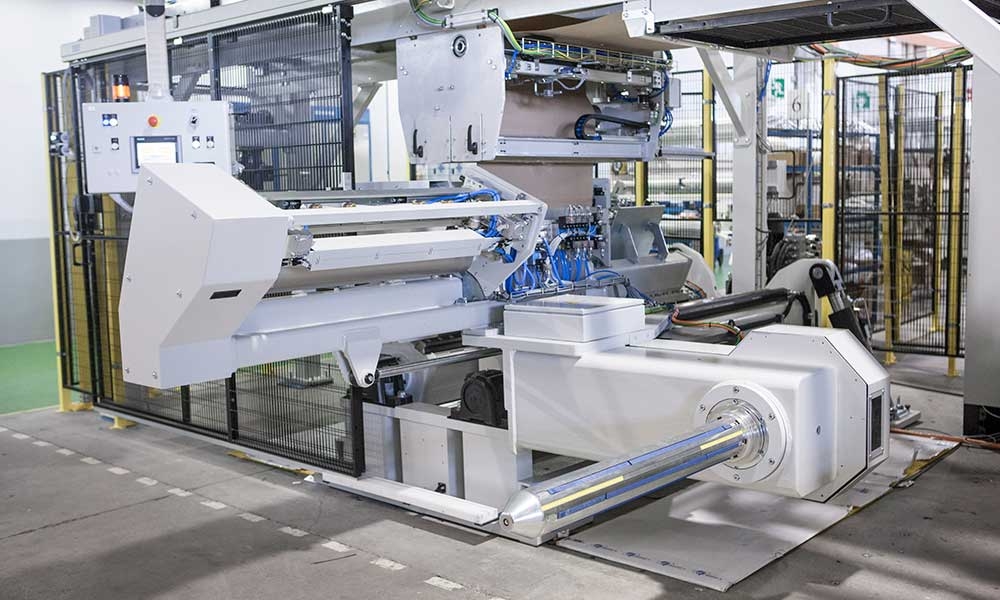

Special splicer for narrow reels

MTORRES has designed a new single-arm unwinder, CANTILEVER type, with high-speed automatic splicing, especially suitable for working with narrow reels (up to 900 mm wide), capable of splicing at speeds of up to 450 m/min with constant tension control. It can make overlapped splices without glue and ‘butt’; even, as an option, it can splice to register.

It is a perfect solution in coating, extrusion, lamination and printing processes.

One of the main advantages of the splicer TORRESLITE, is that it is capable of splicing while maintaining line speed but with high reliability in the splice: fewer machine stops, greater productivity.

The MTORRES TORRESLITE Splicer eliminates the tail of the splice, which means that subsequent treatments in extruders, printers, etc. they do not suffer when the splice passes through the line. Result: reduction of material waste.

| Options | improvement area | |

|---|---|---|

| R.O.C. 1) | Automatic splicing to minimize waste | Raw material savings |

| Double adhesive | Second Adhesive Application | Process quality |

| Splice in record | splice in print log | Process quality |

| External group (included in rack) | Unwinder band tension isolation - process | Process quality |

| Aligner | Band Alignment | Process quality |

| Special rollers | adaptation to demanding bands | Process quality / coverage range |

| Unwind motors | Unwind Control | Process quality / maintainability / energy saving |

| Lanes | Reel handling | Process efficiency - productivity / ergonomics |

| Elevator - Peeler | Reel handling | Process efficiency - productivity / ergonomics |

| Other shaft diameters | axes | customization |

| Shaft adapters | axes | customization |

| "Factory Towers" | Operational availability monitoring and improvement tool for productivity improvement | Process efficiency - productivity |

| Rockwell Platform | control | customization |

| USA Regulations | Regulations | customization |

| MT unwind tests | Tests | Optimization |

| Other non-CE language | Documentation | customization |

| Imperial unit of measure | Documentation | customization |

| Recommended Spares Pack | Spare Parts | Maintainability / efficiency of the process |

1) for substrates from 120/130 gsm.

The splicing is done when the paper strip completely detaches from the mandrel.

The strip must be attached to the mandrel in its entire width, it cannot be partially detached from it.