CTS Splicer

High performance and reliability with very low maintenance.

Dual Splicing unit

Unit with double preparation and splicing station and horizontal movement to move to the different preparation positions. Versions for overlap splicing (without glue) and face splicing (edge to edge).

Vacuum splice preparation

Vacuum systems for fast splice preparation, with different configurations depending on the grammages.

Splice photocells

Enables emergency splicing at the end of the reel, starting the splice cycle automatically in case of web breakage or paper end.

Web tension adjustment

Rocker roller activated by 1 hydro-pneumatic cylinder, used on the CTS-B model. Rocker roller activated by 2 pneumatic cylinders and electronic position control. Also installed on the CTS-E model.

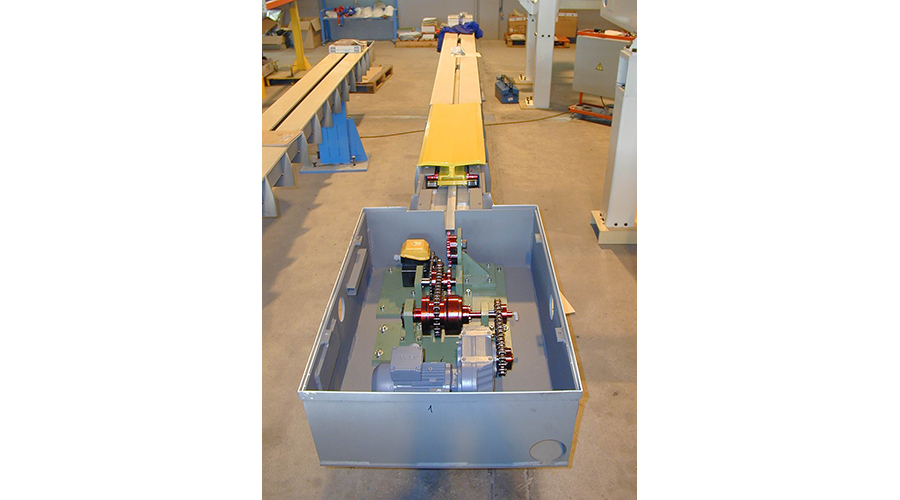

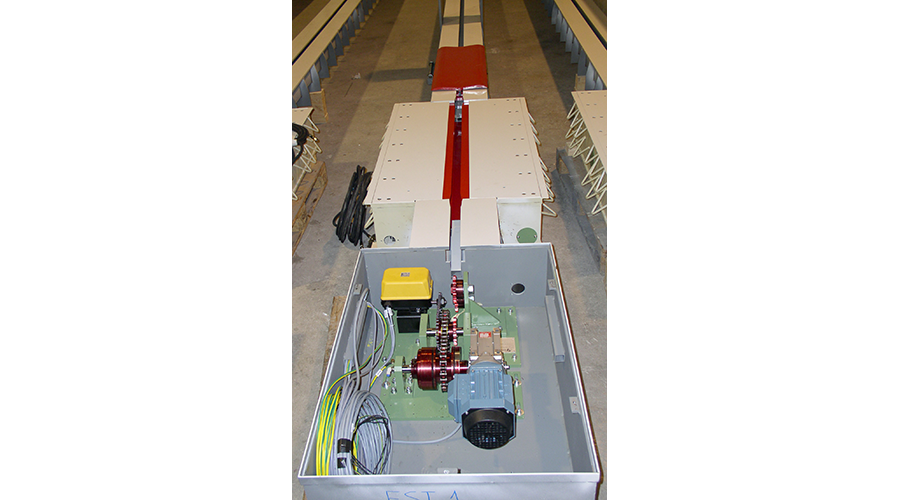

Flywheel

Based on classical mechanical principles, it improves reliability in splices with low grammage paper and is essential for photocell splices at the end of the reel.

Control Panel

The operation panel with centralized controls facilitates the execution and control of operations. The touch screen is the optional help element that allows full control of the screen and is installed as standard on the CTS-E model. Through a password you can access parameters that facilitate machine maintenance. All splicer models have side controls for coil preparation.

Electricity cupboard

Depending on the type of machine, these can be controlled by relays, in the most basic versions or by different PLC models, with which complex calculation functions are carried out for correct brake control. In the highest versions of the series it is possible to have communication via modem for supervision of the machine by our technicians without the need to travel.

| CTS-E Settings | Improvement Area | |

|---|---|---|

| External Pull and Brake | Unwinder web tension isolation - process | Process quality |

| Reel Alignment | Web Alignment | Process quality |

| Special rollers | Adaptation to demanding webs | Process quality / coverage range |

| Flywheel | Support system for warehouse exit in splice sequence | Process quality |

| Heating resistors | Splice preparation | Process quality |

| Butt Splice | Butt splice | Process quality |

| Automatic splicing (scrap reduction system) | By meters / Diameter – remainder < 5 m + HMI | Scrap reduction / savings / process efficiency |

| Siemens HMI | Ergonomics | |

| Motor unwinding | Unwind Control | Process quality / maintainability / energy saving |

| Auto load / unload | Reel handling | Process efficiency - productivity / ergonomics |

| Conveyors | Reel handling | Process efficiency - productivity / ergonomics |

| Core finder | Reel handling | Process efficiency - productivity / ergonomics |

| Lifting - Peeling | Reel handling | Process efficiency - productivity / ergonomics |

| Other core diameters | Cores | Customization |

| Core Adapters | Cores | Customization |

| Rockwell Platform | Control | Customization |

| UL Regulations | Regulations | Customization |

| MT unwind tests | Tests | Optimization |

| Other non-CE language | Documentation | Customization |

| Imperial unit of measure | Documentation | Customization |

| Recommended Spares Package | Spare parts | Process maintainability / efficiency |

Rails

Flywheel

Head Splice Unit

Head Splice Unit

Corefinder