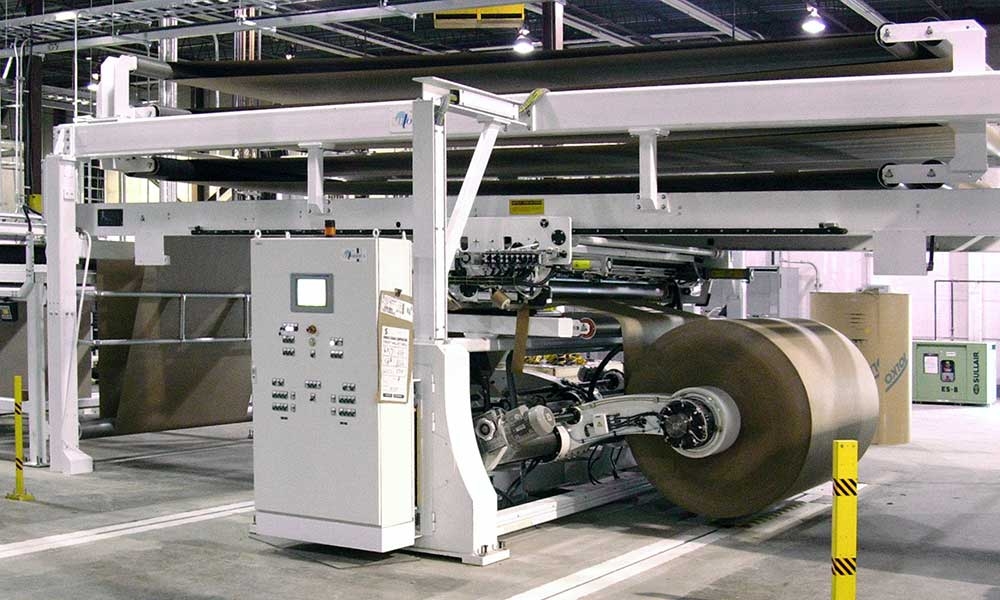

LTP Splicer

LTP Splicer

An ideal high speed splicer for processes with high added value

LTP Splicer

The model LTP is a high speed and high performance splicer that MTorres offers in two versions: LTP-70 with a splice speed up to 500 m/min (1640 fpm) and LTP-90 with a splice speed up to 670 m/min (2200 fpm). It is ideal for paper, cardboard and other rigid materials such as laminated papers used in printing processes, extrusion coating, and in other numerous applications. The LTP splicer can work with both floor pick-up and turret splicers.

Splicing unit to ‘testa’

It eliminates the splice tail and even the overlapping of the two bands so that the thickness is not increased. Thanks to the vacuum system and its ergonomic position, the operator can easily and quickly prepare the splice.

Multiple Storage

Stores enough paper to feed the line during the splicing process, without the need to reduce the working speed. The storage is controlled by a floating system activated by a clutch or by a servo-motor (depending on the model), and an encoder that indicates its position at all times.The rollers are made of aluminum in their standard configuration and carbon fiber in the case of low grammage materials or for high speed requirements.

Tension control

The MTorres patented system for tension control offers different tension control systems according to the necessary configurations and features. LTP can incorporate a rocker arm at the exit of the hooper or the hooper itself works as a rocker arm during the unwinding process to maintain constant band tension. A set of load cells placed on low inertia rollers provide an accurate measurement of the actual band tension.

| LTP Settings | Improvement area | |

|---|---|---|

| R.O.C. 1) | Automatic splicing to minimize waste | Raw material savings |

| External group (included in rack) | Unwinder band tension isolation - process | Process quality |

| Aligner | Band Alignment | Process quality |

| Special rollers | Adaptation to demanding bands | Process quality / coverage range |

| Motor unwinding | Unwind control | Process quality / maintainability / energy saving |

| Auto load/unload | Reel handling | Process efficiency - productivity / ergonomics |

| Lanes | Reel handling | Process efficiency - productivity / ergonomics |

| Core finder | Reel handling | Process efficiency - productivity/ ergonomics |

| Elevator - Peeler | Reel handling | Process efficiency - productivity / ergonomics |

| Other cone diameters | Cones | Customization |

| Cone Adapters | Cones | Customization |

| "Factory Towers" | Operational availability monitoring and improvement tool to improve productivity | Process efficiency - productivity |

| Rockwell Platform | Control | Customization |

| USA Regulations | Regulations | Customization |

| MT unwind tests | Tests | Optimization |

| Other non-CE language | Documentation | Customization |

| Imperial unit of measure | Documentation | Customization |

| Recommended Spares Pack | Spare parts | Process maintainability / efficiency |

1) For substrates from 120/130 gsm.

The splice is made when the paper web is completely detached from the mandrel.

The web must be attached to the mandrel over its full width, it cannot be partially detached from the mandrel.

Downloads

You will find all the technical information specified in the product sheet.