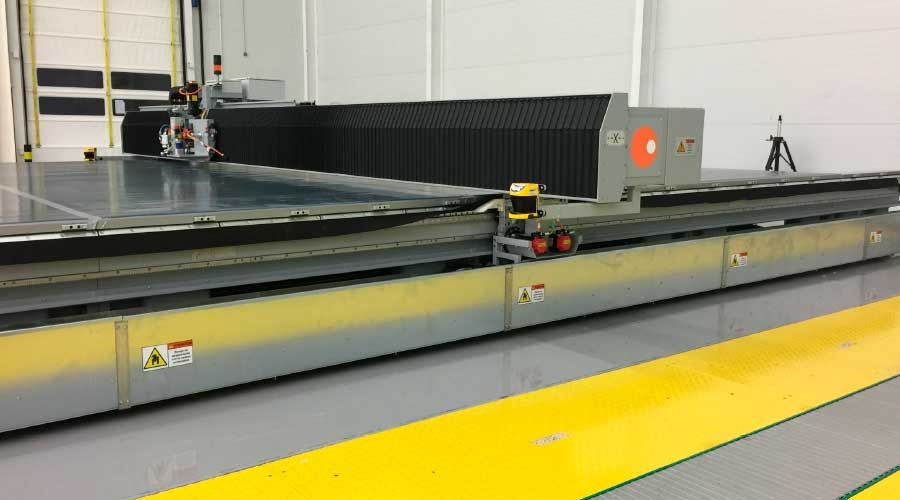

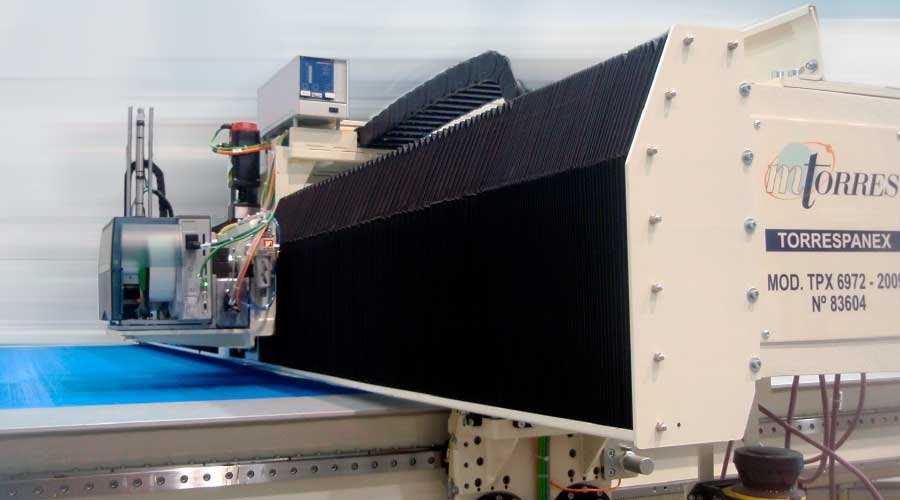

Ultrasonic composite cutting machine - TORRESPANEX

Specially designed for high speed cutting of aircraft components

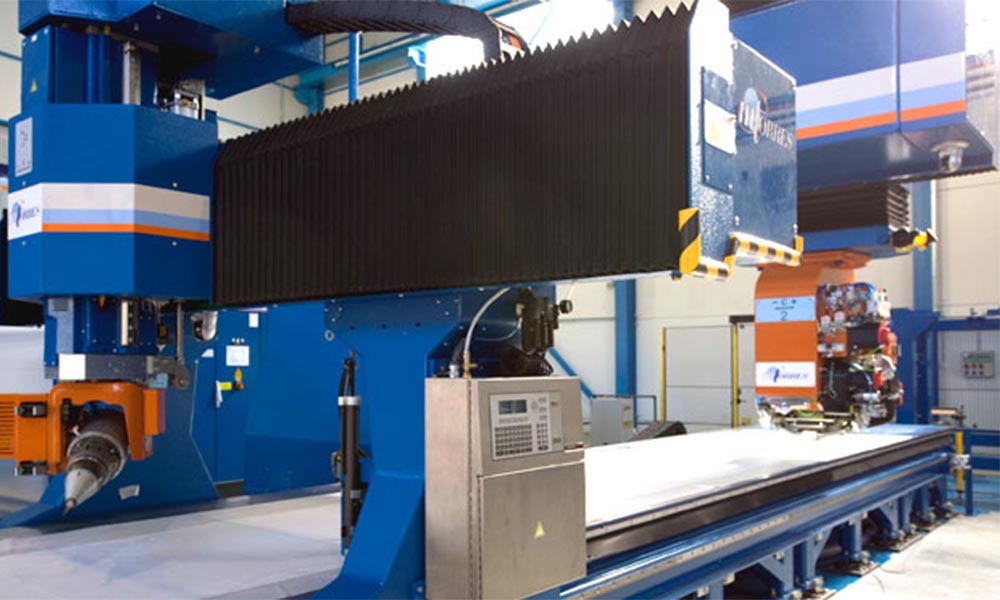

The torsion-free lightweight and robust gantry concept allows the machine to provide maximum acceleration-deceleration at the highest forward speeds.

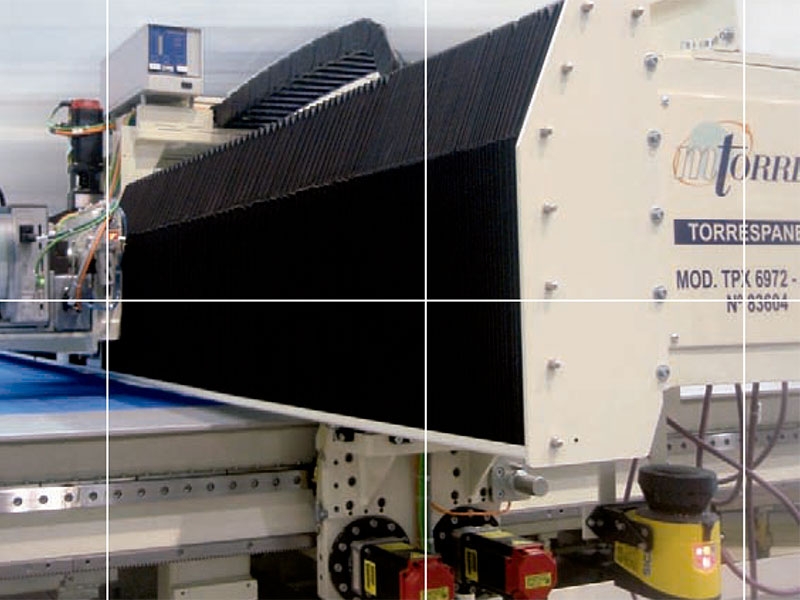

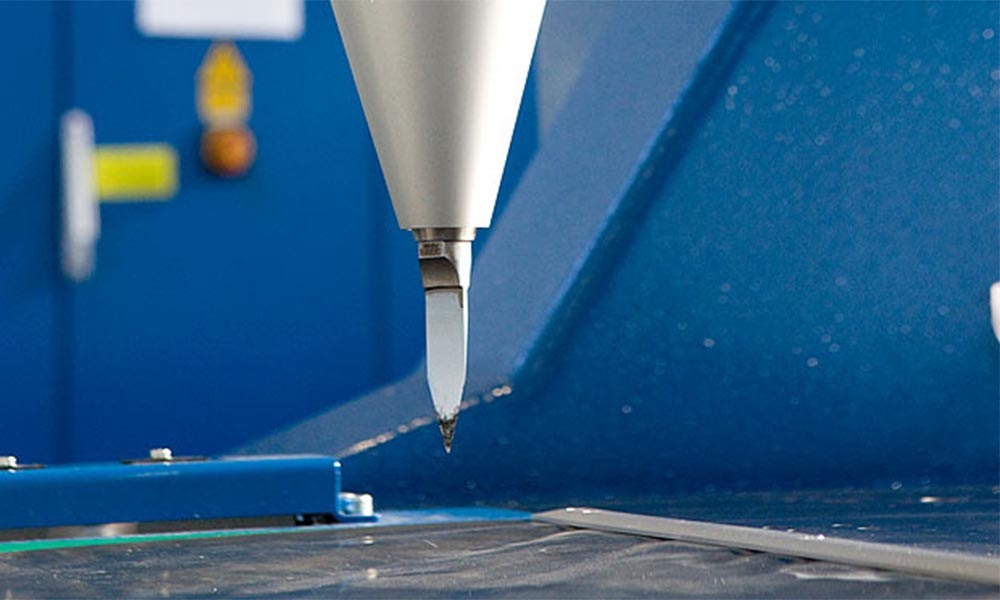

An ultrasonic cutting system provides the appropriate high-frequency vibration capabilities for optimal cutting conditions and maximum feed rates. The well-proven modular machine system is the basis for each individual application.

The gantry cutting machines of TORRESPANEX are built in various sizes to meet the requirements and specifications of the client. An automatic tool changer is optionally available for the use of different SONOTRODES, as well as part labeling capabilities.

DATA: Ultrasonic cutting technology is widely used in the aerospace industry to manufacture carbon fiber components.

The machine can also include a vacuum table to support the component to be cut or a conveyor belt to facilitate the loading/unloading of the piece.

Applications may include net cutting of contoured composite fuselage panels, wing skins, composite structures, frames, stringers, etc.

| Settings | Options |

|---|---|

|

As per customer specifications |

Automatic Sonotrode changer |

|

2D & 3D cutting |

Automatic cutter change and calibration system |

| Straight and bevel cut | Cutter break detection system |

| Cutting speed up to 60m/min | Labeling system |

| Integrated with vacuum table | 2D Rototranslation system |

| Integrated with other layup technologies (ATL & AFP) | Vacuum table mapping sensor |

| Conveyor table | |

| Nesting Software | |

| MTorres post-processor | |

| Production support service |

Ultrasonic Ply Cutting