Automatic Fiberplacement Machine - TORRESFIBERLAYUP

Maximum productivity and return on investment

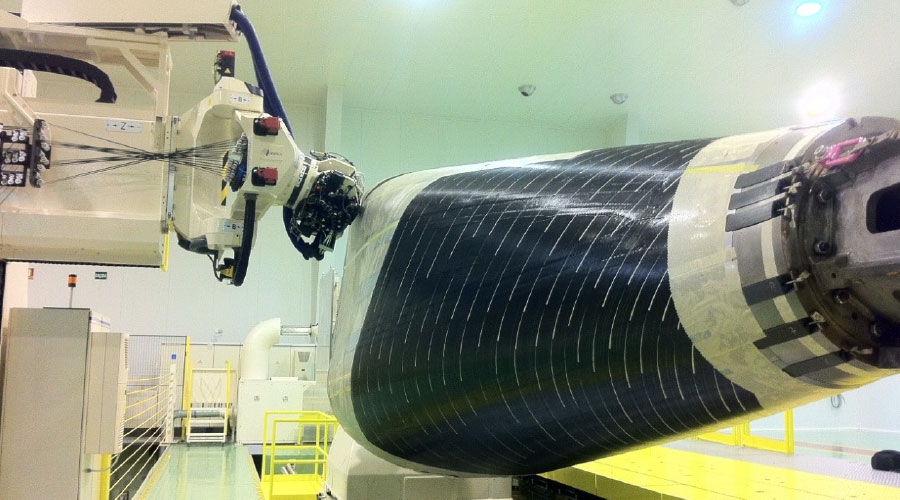

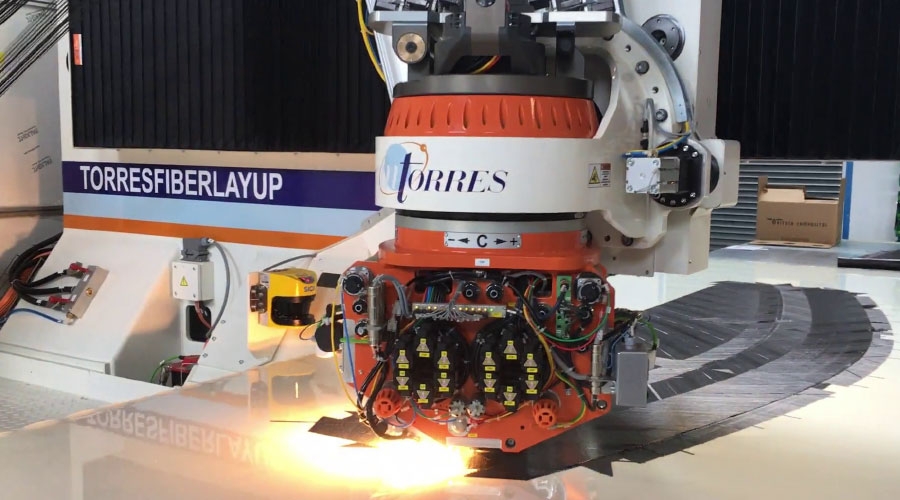

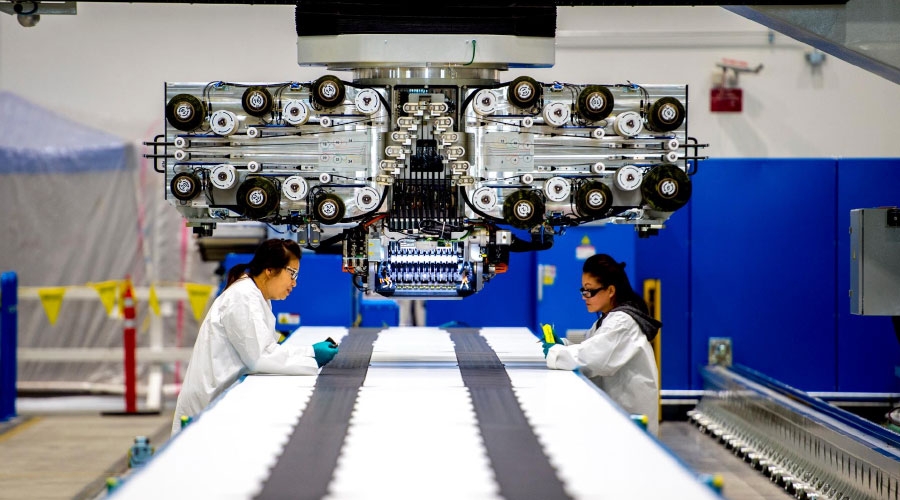

TORRESFIBERLAYUP is an automated fiber laying machine designed to provide the highest productivity when it comes to manufacturing carbon fiber components high contour for aircraft, from simple parts to complex curvatures such as fuselage panels or wing spars. 2D parts, such as stringers, can also be made in AFP, thanks to its huge savings in waste material.

Its unique PATENTED trailer cutting and adding system with a full speed design concept allows the machine to consistently and accurately cut, add and place at 60mpm, ensuring the highest productivity fiber placement solution available on the market. Placement speeds can reach 100 mpm on the latest machines.

This is a modular concept based on a multi-machine architecture with automatic head swapping capability allowing any machine configuration in terms of number of rows, as well as the width of the belt and the size of the machine.

Both Boeing and Airbus have identified AFP technology as the most productive solution for manufacturing CFRP fuselages (both male and female) and wing components (Skins, Spars and Stringers).< /p>

Furthermore, the machine can be supplied under different architectures, gantry type, robotic arm, column type, with or without Head Stock - Tail Stock system for revolution parts, etc.

A programming/simulation software package very advanced and sophisticated, TORFIBER, allows the programmer to generate, simulate and analyze the part program, within a CATIA 3Dexp environment, before the postprocessor provided by MTORRES generates the CNC program.

Fiberplacement

Cantilever

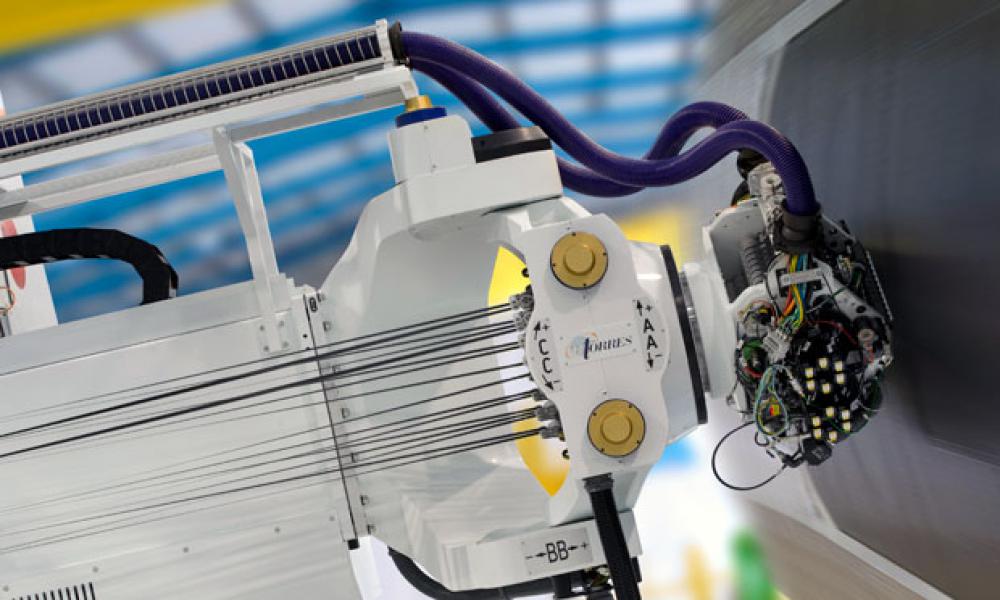

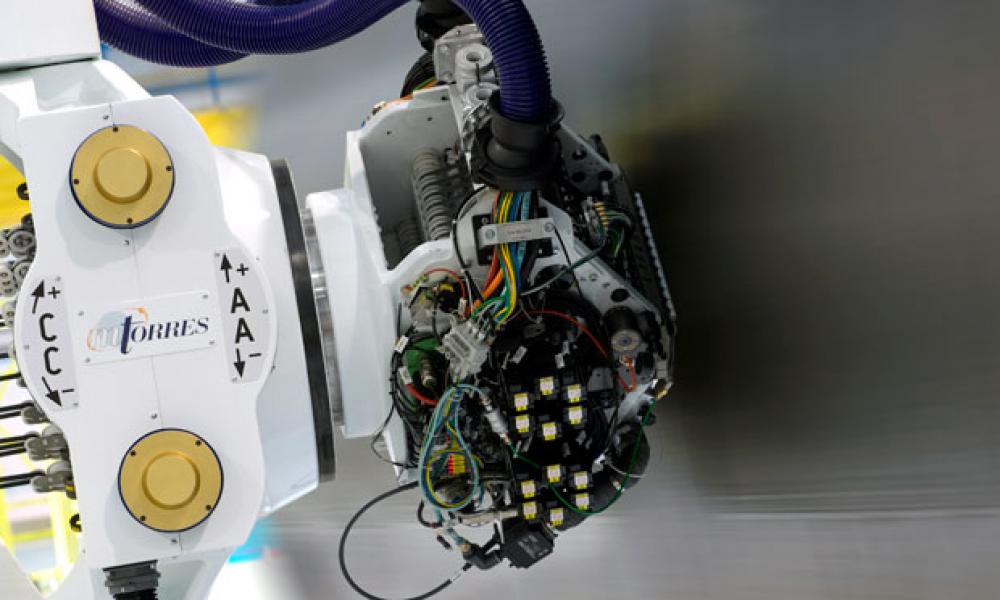

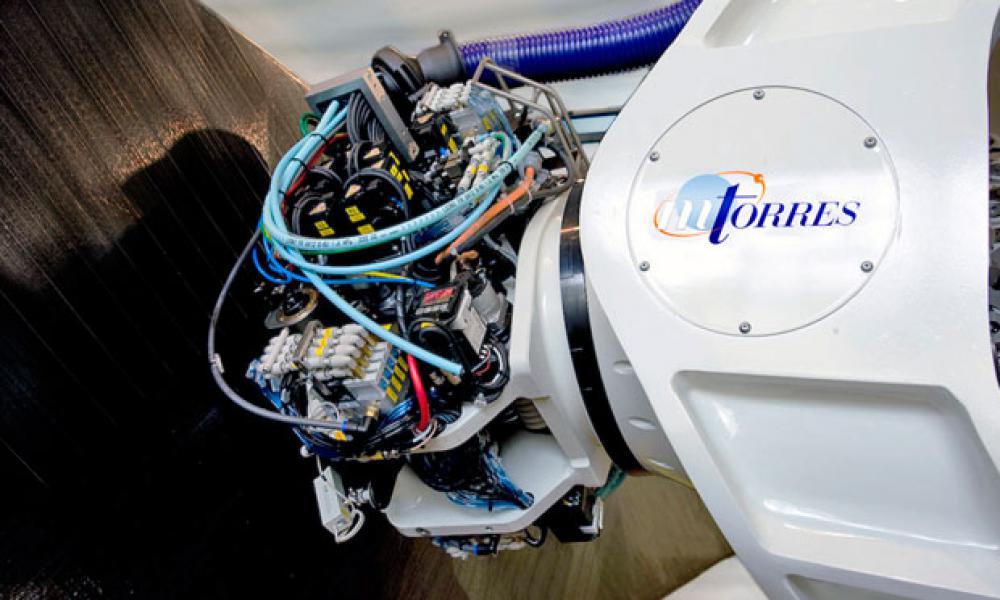

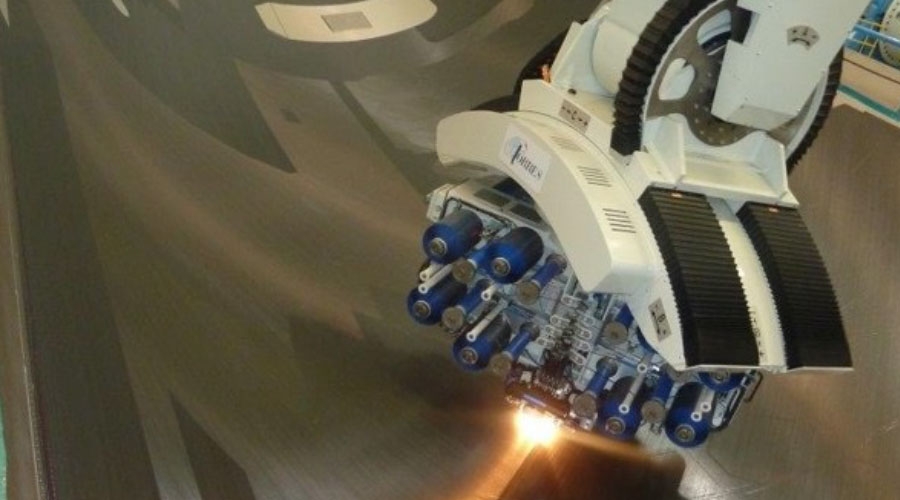

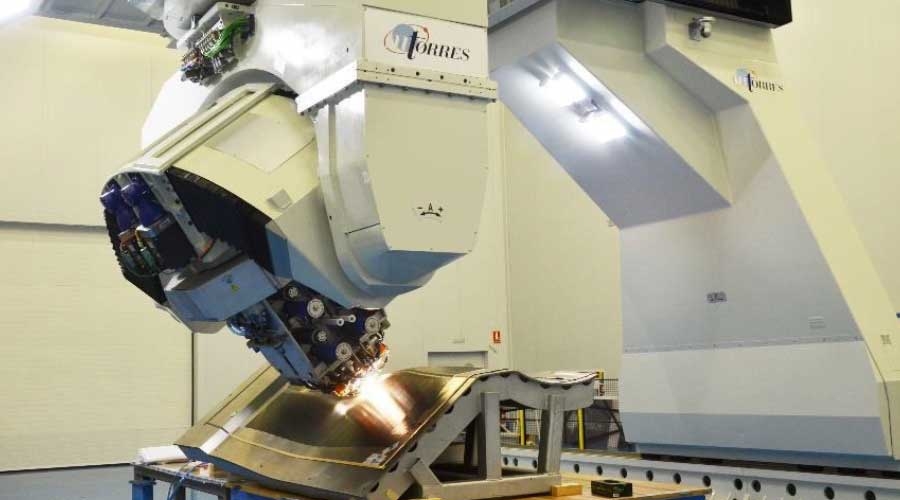

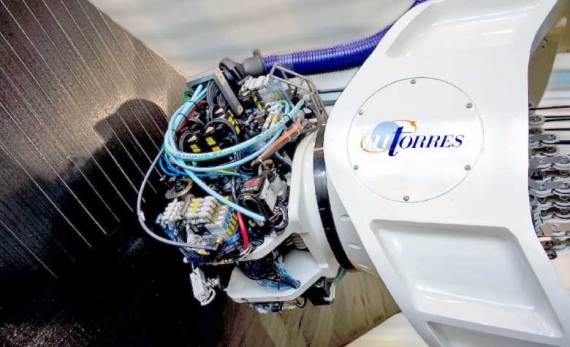

Robot AFP

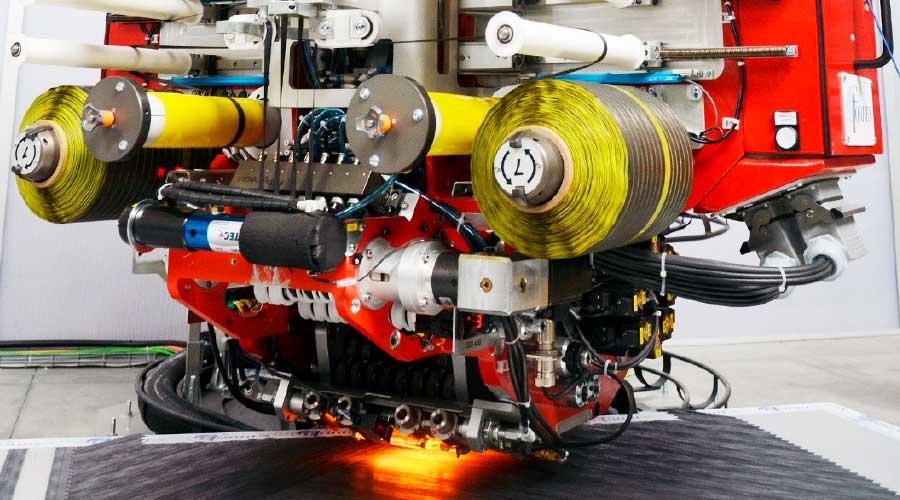

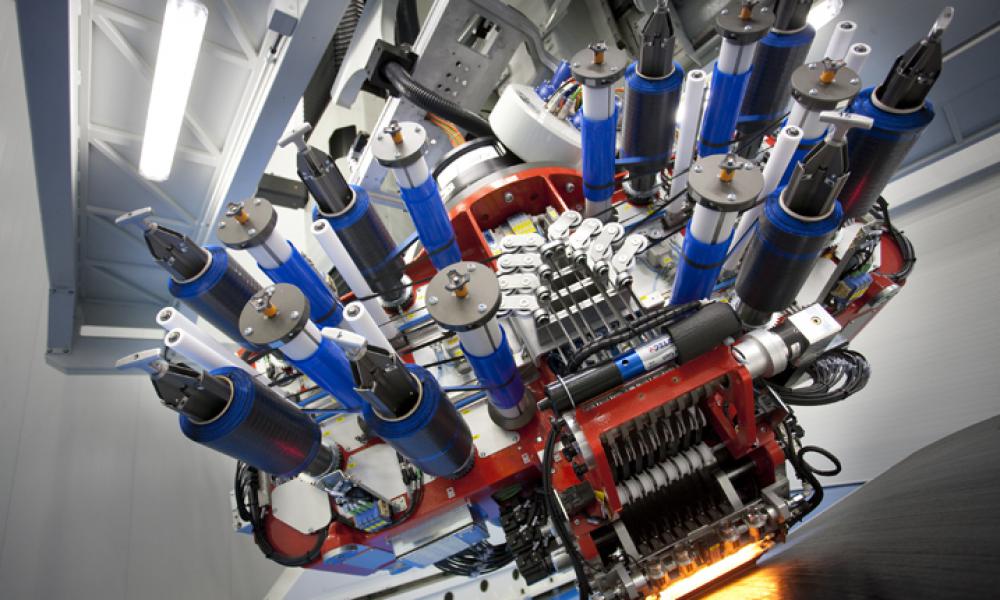

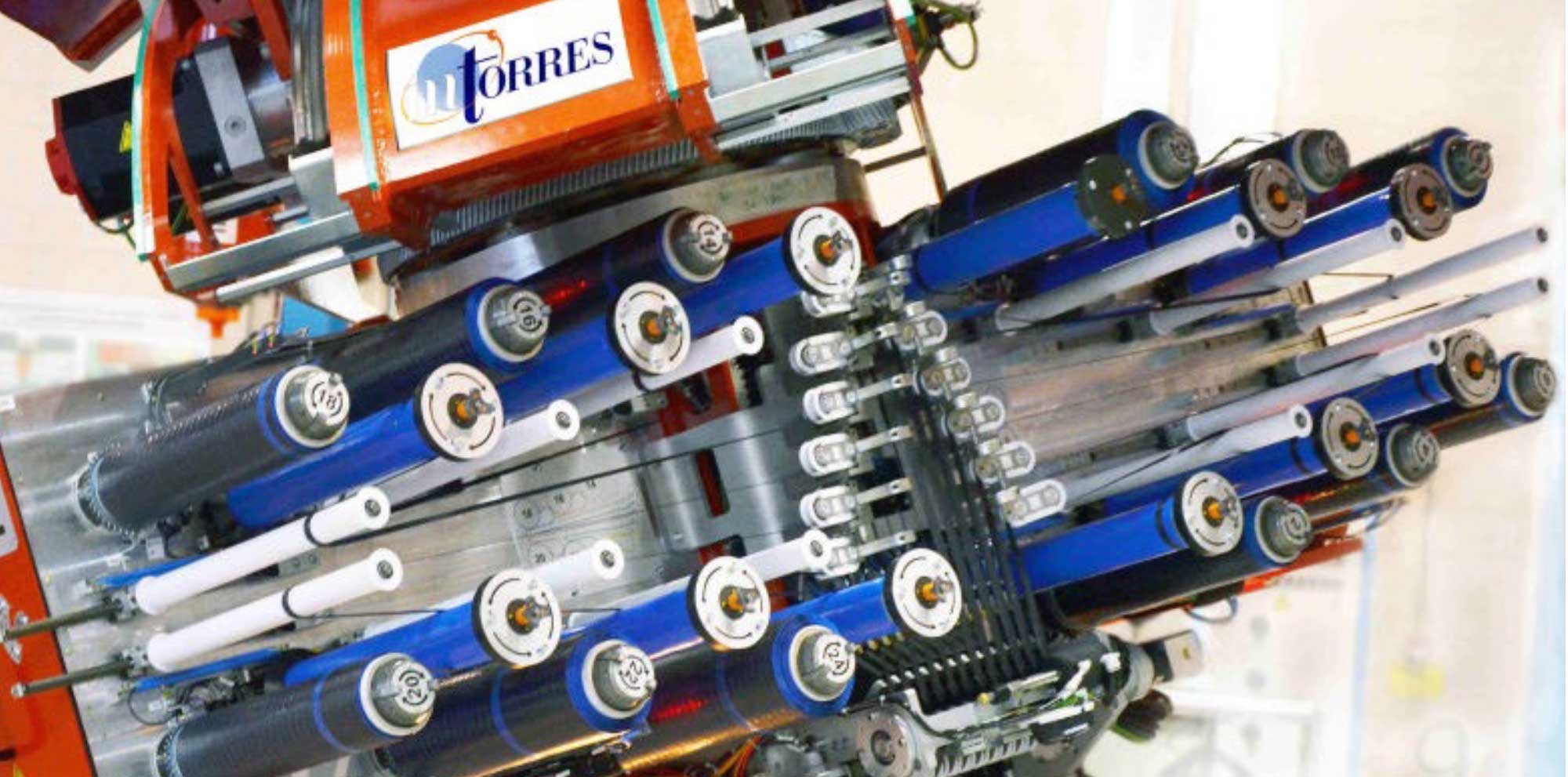

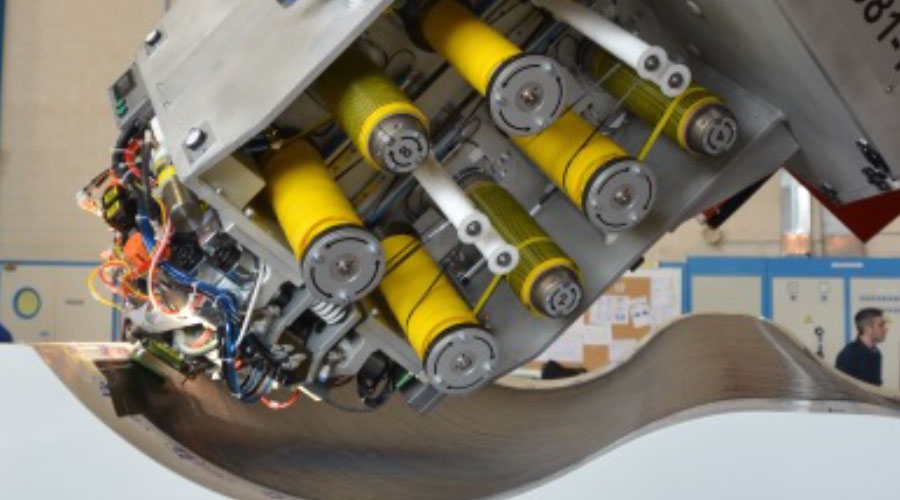

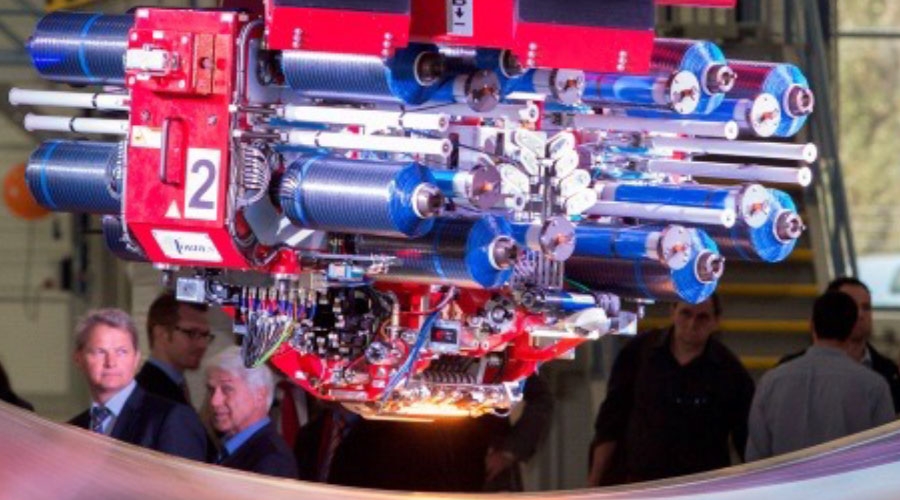

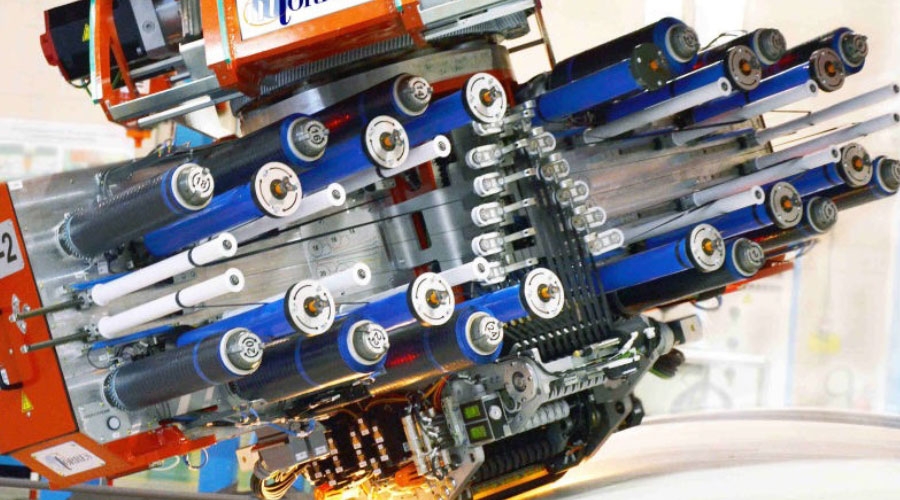

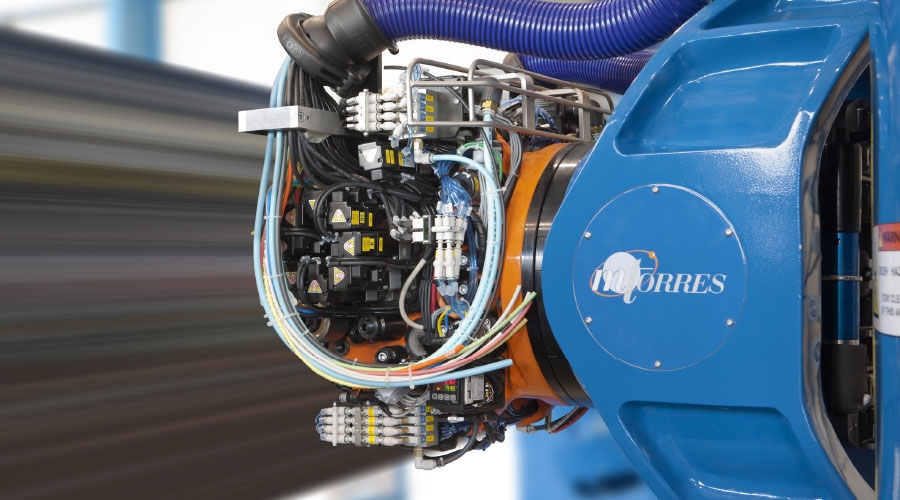

AFP HEAD SPECIFICATIONS

- From 1 to 24 Tows

- Any tow width 1/8”, ¼”, ½”, 1,5” & 2,0” available

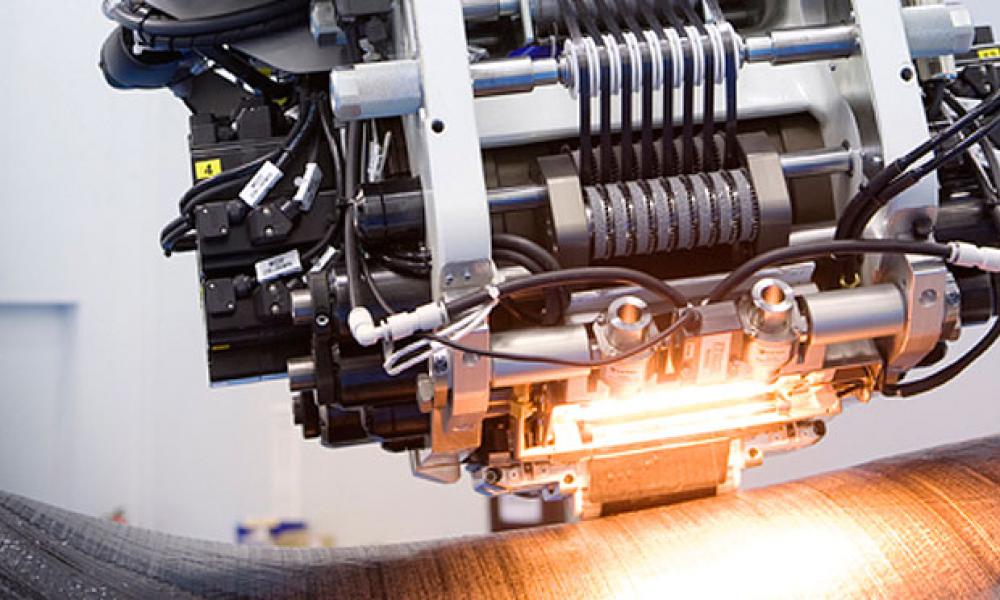

- Valid for any slit tape material (Thermoset, Thermoplastics and Dry Fiber materials)

- Add cut on the fly up to 60 m/min

- Min Tape length 132mm

- ±2,5mm of End-placemnet Tolerance at 60 m/min

- Up to 11 Kg spools

- Automatic exchangeable head capability to combine different tape formats, materials and technologies into the same layup cell.

TORRESFIBERLAYUP OPTIONS

- Own programming and simulation software TORFIBER

- Hybrid (ATL/AFP) configuration

- On Line part quality Inspection

- Integrated Laser projectors

- Rotary systems (Headstock/Tailstock) up to 90 Tons

- Laser heating system for Thermoplastics layup

- Automatic tow adjustment system

- Automatic head stand

- Ultrasonic ply cutting system

- Wireless pendant

- Dual working zone

AFP Heads

20x 1,5” AFP head

16 x 2,0” AFP head

8 x ¼” AFP head

16 x ¼” AFP head

24 x ¼” AFP head

Machine Architectures

PORTAL GANTRY TYPE

CANTILEVER TYPE

COLUMN TYPE

ROBOT TYPE

Machine architectures. Portal Gantry

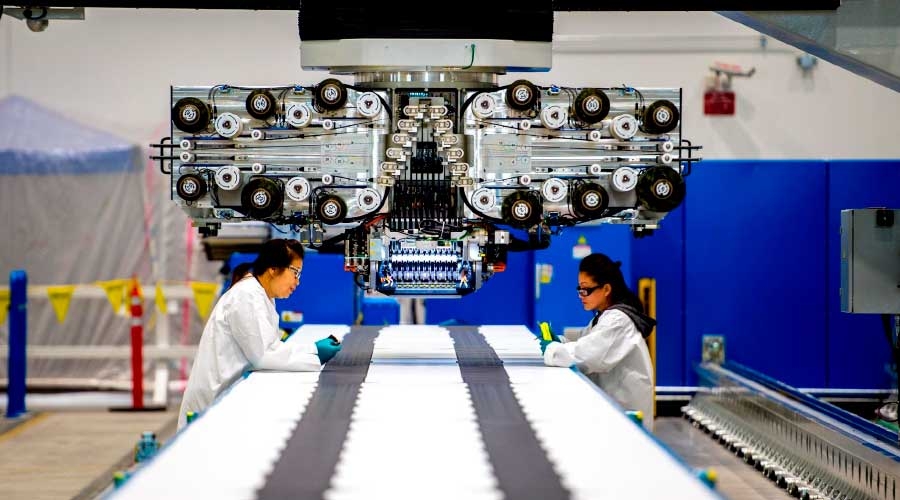

Gantry Settings

- 2D & 3D layup

- Concave and convex large parts geometries

- High dynamics machine

- Simple lay-out easily accessible for operators

- Head exchange capability. AFP-AFP and AFP-ATL

- Up to 24 tows per AFP head

Gantry

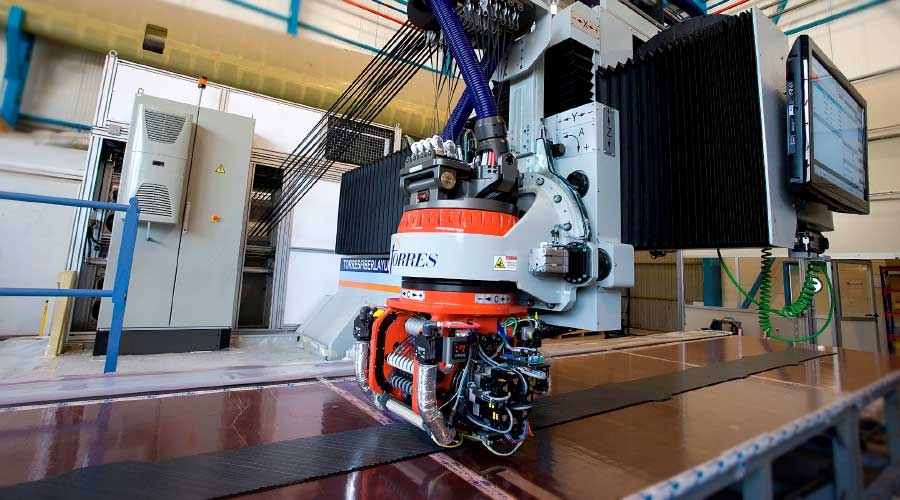

Machine architectures. Column

Settings. Machine Architectures. Column

- 3D & 2D layup

- Specially Indicated for revolution parts

- Good accessibility

- Integrated with rotary tooling up to 90 Tons

- Up to 24 tows per AFP head

Column

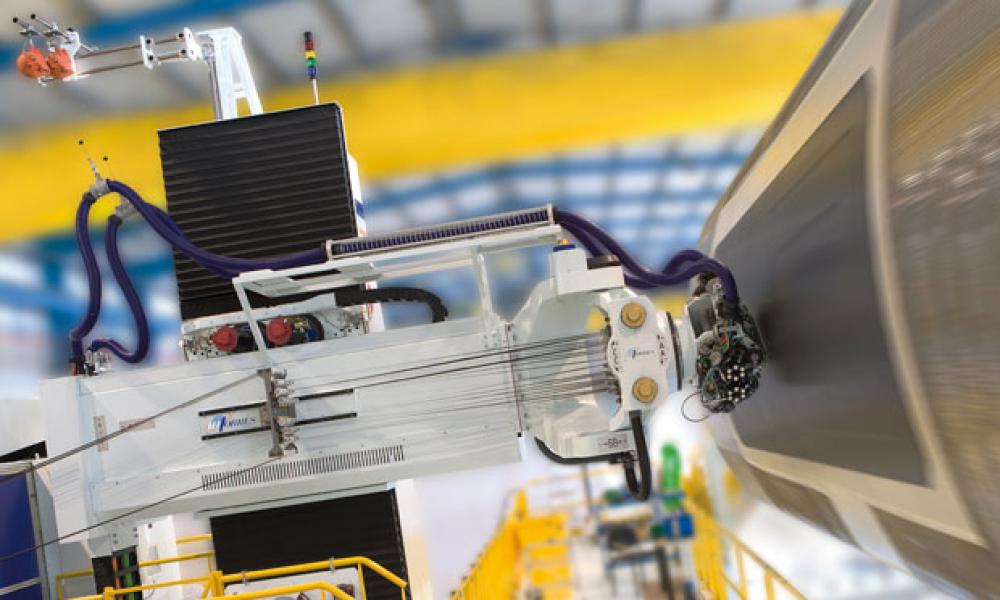

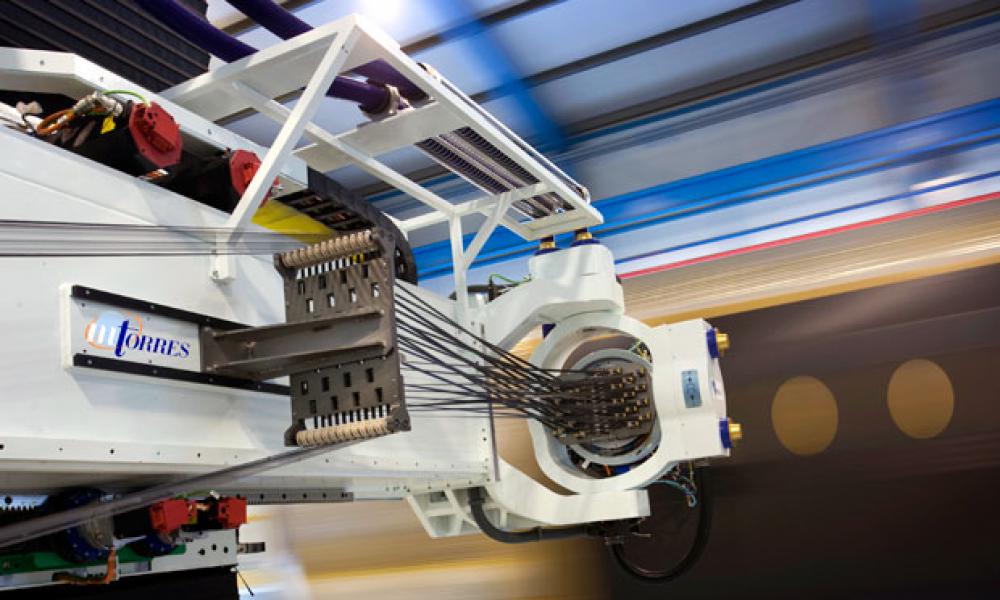

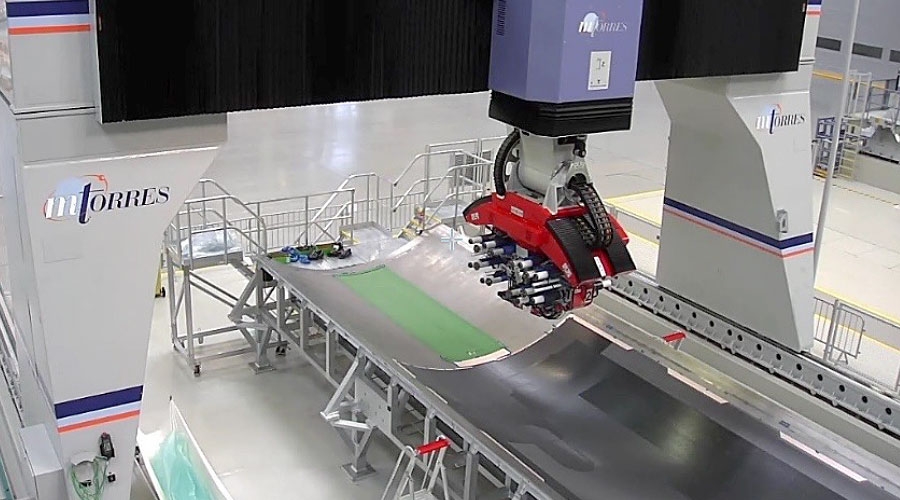

AFP Machine architectures. Cantilever

Settings. Machine Architectures. Cantilever

- 2D Layup

- Reduced foundation requirements

- Easily Accessible for operators from one side of the table/tool

- Lightweight & High dynamics machine

- Head exchange capability. AFP-AFP and AFP-ATL

- Up to 24 tows per AFP head

- Smaller footprint and height than standard gantry

Cantilever

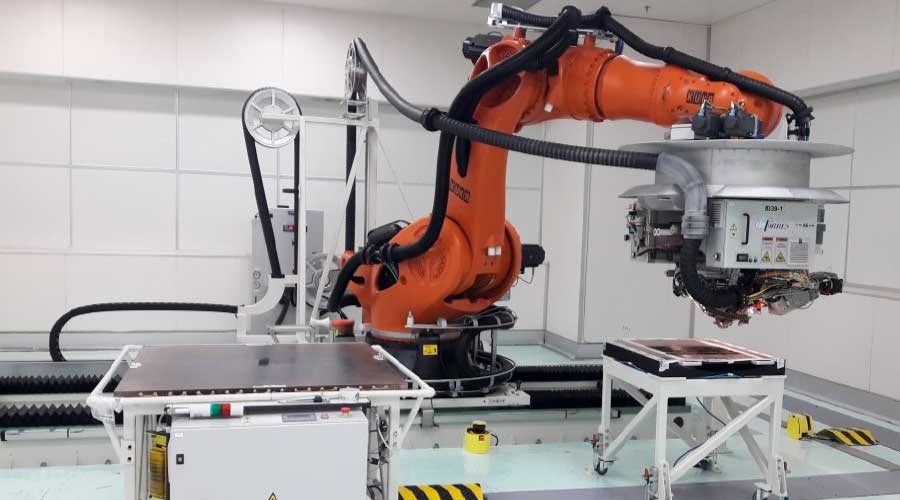

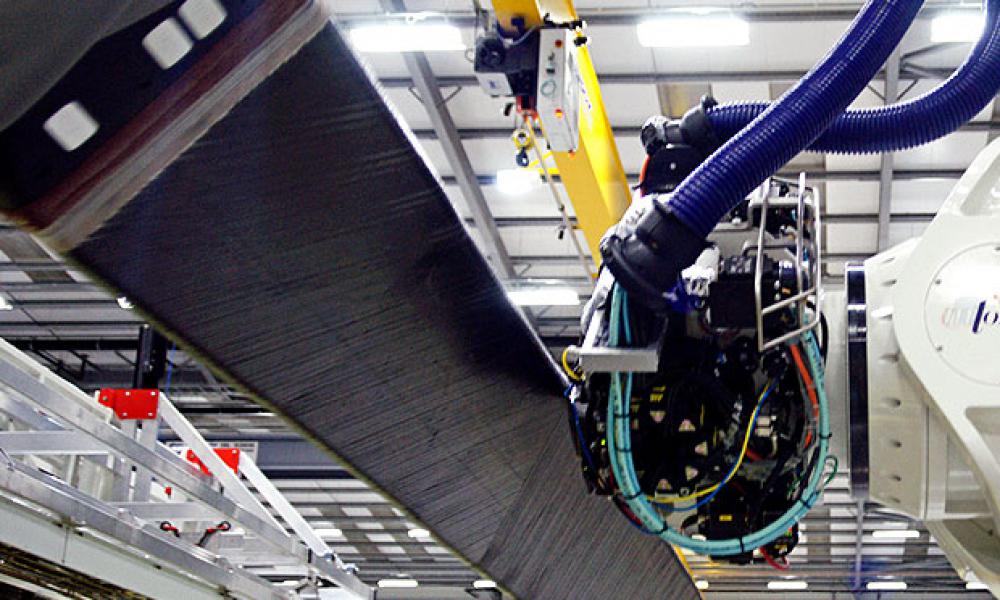

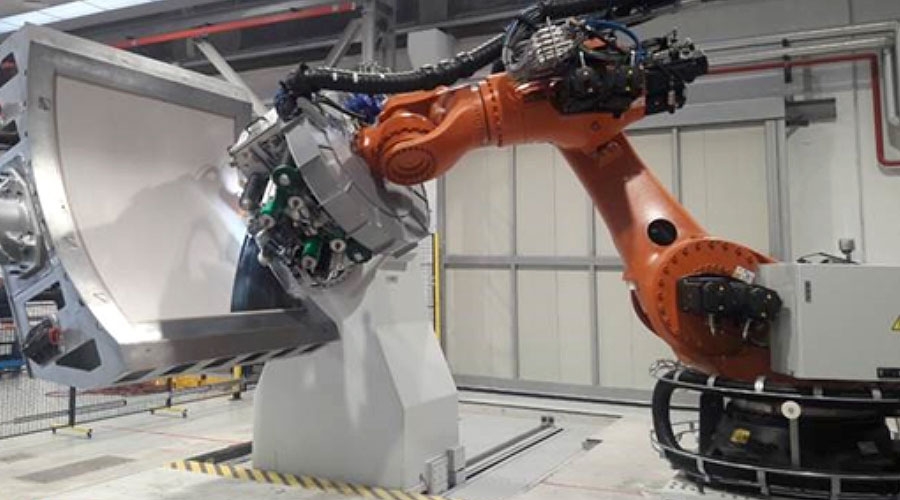

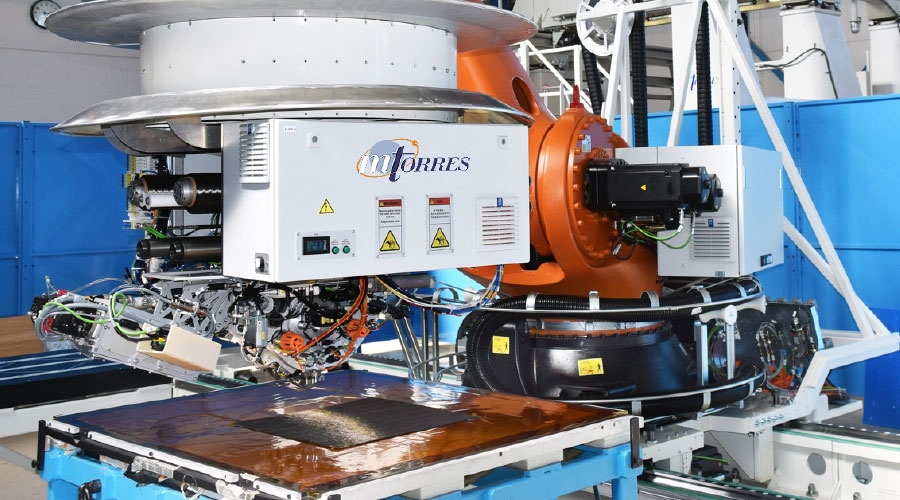

AFP Machine architectures. Robot

Settings. Machine Architectures. AFP robot

- On ground. No special foundation requirements

- Small footprint

- Integrated with rotary tooling to build revolution parts

- Head exchange capability. AFP-AFP and AFP-ATL

- Up to 16 tows per AFP head

- Very versatile architecture. Easily integrable with other technologies

- KUKA robotic arm with SIEMENS controller

- Integrated with X carriage and 6’ axis

Robot