30-09-2022

TorresFactory 4.0, solution for your digitalization needs

The MTorres Vision is to “transform manual and heavy tasks with extremely high-quality standards into automated processes”.

The digitalisation tools, what we call digital twin, created by Mtorres provides to our customers:

- A product design cycle time reduction.

- A shortened Machine Set up and operation

- Earlier stage Processes decision taking

- Overall Product quality improvement

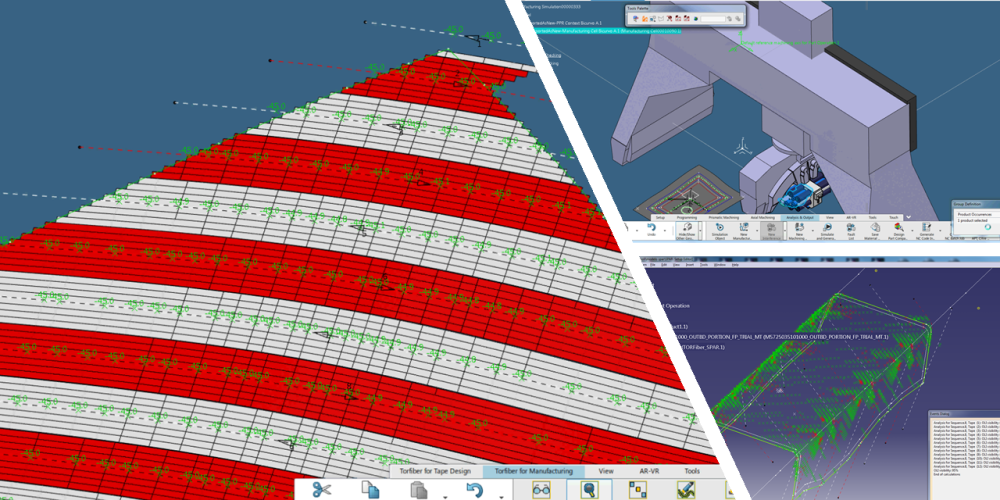

SIMULATION BASED DESIGN

With more that 25 years of experience in the development and creation of software CAD-CAM tools for composites manufacturing (Torlay and Torfiber), Mtorres is going one step further: simulating the composites key process parameters and advance sensorization of the machine. Interfacing with part design applications is needed in order to speed up the design to manufacturing process in the digital world avoiding costly composites process adjustments and preparing to production high rates.

FROM EQUIPMENT TO PLANT SIMULATION

Consistent with its innovation philosophy, MTorres has developed useful virtual tools, not only for the design of individual equipment, but also for cell and plant design phases. These tools are used in the concurrent engineering services provided by Mtorres for the design of complex and challenging production plants since the Product Concept Phase, providing early and optimum production means configuration, well ahead of the actual investing time.

On the other hand, Mtorres can provide "automation digital twins" of individual equipment, virtual commissioning, extremely important for iterative process improvements during the commissioning phases or rate growth projects.

IN-PROCESS PART QUALITY DATA

Sensors such as Online Inspection System, based on Artificial Intelligent algorithms and neuronal networks, allows the product digitation ensuring process traceability and product quality. Additionally, the collection of the measured key process parameters during lay-up (pressure, tension, temperature, adherence) makes possible the so called "as-built digital twin" of the part.

EDGE DATA ANALYTICS

The introduction of new sensors and on-line quality information into the process makes possible now that current availability and productivity issues could be predicted and detected before they really happen. This means that Mtorres machines could self-diagnose and in the long-term self-tune and self-repair. For that purpose Mtorres has developed a series of self-diagnosis routines, a platform that gathers the relevant machine data, calculate the key process indicators and trigger predictive alarms. This processed information is also sent to customer third party’s applications (MES, ERP) using standard protocols.

In summary, Mtorres has created specific technology for the complete digitalisation cycle, which enables proactive Industry 4.0 improvement services during the complete equipment lifecycle.